Factory Cheap Hot Bottle Cap Sealer - Rotary Capping Machine for 5ml filling sealing – BRENU

Factory Cheap Hot Bottle Cap Sealer - Rotary Capping Machine for 5ml filling sealing – BRENU Detail:

The capping machine is also called pressure machine, sealing machine or clock machine, and its main use is plastic bottles and glass bottles.Here is one of cosmetic line ,professional automatic essential oil filling and capping machine mainly includes various essential oils, nail polishes, perfumes, makeup removers, etc., using PLC touch screen to control the peristaltic pump filling, with high filling accuracy, with automatic cleaning function, filling, The upper plug, the upper cover, and the cap screwing are all completed in the imported cam divider, with high precision, stable operation, reasonable design, easy operation and maintenance, and fully meet the requirements of the new version of GMP.

HERE IS ONE OF COSMETIC LINE ,PROFESSIONAL AUTOMATIC ESENTIAL OIL FILLING AND CAPPING MACHINE , MAINLY INCLUDES VARIOUS ESSTIAL OILS , NAIL POLISHES , PERFUMES , MAKEUP REMOVES, ETC, USING PLC TOUCH SCREEN TO CONTROL THE PERISTALTIC PUMP FILLING , WITH HIGH FILLING ACCURACY , WITH AUTOMATIC CLEANING FUNCTION ,FILLING , THE UPPER PLUG, THE UPPER COVER, AND THE CAP SCREWING ARE ALL COMPLETED IN THE IMPORTED CAM DIVIDER , WITH HIGH PRECISION, STABLE OPERATION , REASONABLE DESIGN , EASY OPERATION AND MAINTENANCE ,AND FULLY MEET THE REQUIREMENTS OF THE NEW VERSION OF GMP

| items | Technical | Detail |

| 0 | Model | BSGSEGX-30 |

| 1 | Main power | 2kw |

| 2 | Precision | >99% |

| 3 | capacity | 30-40pcs/min or 60-80pcs/min (depending on bottle and caps) |

| 4 | Working voltage | AC220V/110V 50-60HZ |

| 5 | Dimension | 2000x1250x1600mm |

| 6 | Weight | 550kg |

1. PLC touch screen control, easy to operate and maintain

2. It is convenient to replace accessories and has automatic cleaning function

3. Frequency conversion control, production speed can be adjusted, automatic counting

4. No bottle stop function, automatic start when the bottle comes

5. Made of 304 and 316L stainless steel, fully comply with the requirements of the new version of GMP

PLC INTELLIGENT CONTROL

The independent LCD screen has the function of touch screen speed regulation, and it can be more clear a more comprehesive view of the machine’s running process , real-time monitoring , real-time adjustment,and more precise, at the same time of efficient production, the filling effect is not compromised !

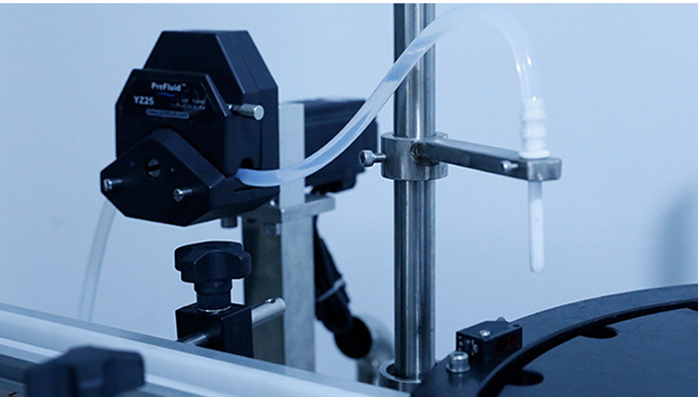

PERISTALTIC PUMP FILLING

Fiber positioning filling , peristaltic pump accurate and quantitative filling , no dripping , no splashing , stable production.

VIBRATING PLATE

High-frequency vibration plate, stable cap release , large-capacity cap placed, reducing manual input , and stable production, with or without cover alarm , full vibration pre-stop and other functions to improve work efficiency

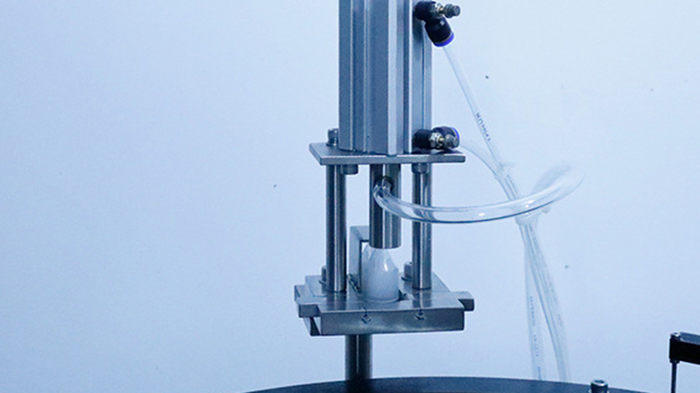

AUTOMATIC COVER HANING

Closely cooperate with the bottle mouth to improve the efficiency of preventing caps , reduce the leakage of caps and the occurrence of no caps and improve production efficiency

CAPPING DEVICE

The capping head is made of special materials ,so the capping speed is fast and accurate , mechanical cam movement, stable and precise operation , through precise cam guide movement, the use of Germany refined torque motor to ensure the stability of the screw cap , while avoiding the damage to the cap due to improper operation

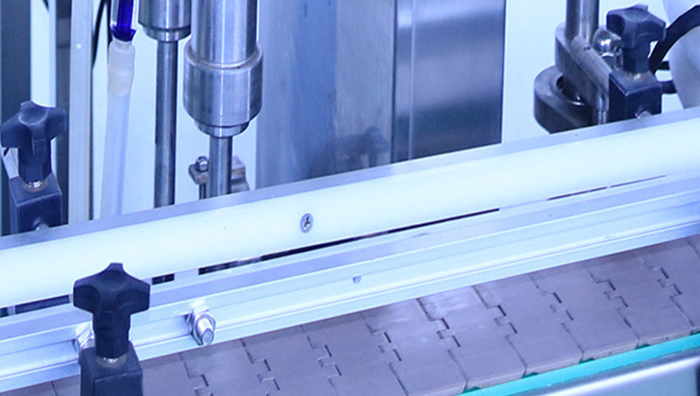

CONVEYOR BELT

Stable conveying of the bottle body, adopting fine grinding motor drive , so that the bottle body can be transported stably without collision , no pouring or hanging

QC GUARANTEE

① all filling or capping machine from our factory ,QC personnel will carefully check the quality of the machine and do power-on test before the package leaves the warehouse.

②all filling or capping machine from our factory , There are special QC equipment to help QC personnel complete the inspection.

③all filling or capping machine from our factory ,QC stipulates that after each inspection, the quality inspection report must be filled in to ensure the quality of customers’ goods.

AFTER-SALES SERVICE

① all filling or capping machine from our factory ,24hours*365days*60minutes online service. engineers, online sales, managers are always online .

② all filling or capping machine from our factory ,We have a complete set of after-sales service process.

Technical engineer :MR.JI (851439108@qq.com)

Online service:Lily(sales2@brenupackmachine.com)

Material Purchase manager:Tina(master@brenupackmachine.com)

Sales chief executive :Jessica(sales6@brenupackmachine.com)

③all filling or capping machine from our factory , If there are quality or other problems with our products,our company’s team will discuss it together and solve it, if it is our responsibility, we will never refuse to make you satisfied.

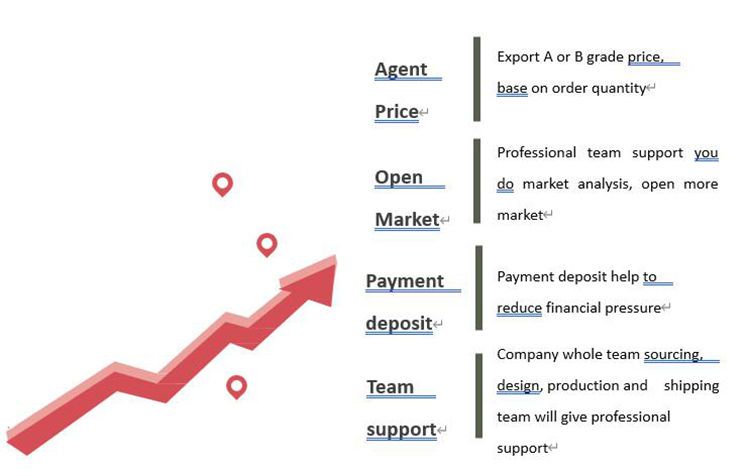

SPECIAL SERVICE FOR OUR AGENT

FAQ

1. Why choose us?

1.1- We have over 30 years experience on machinery making .

1.2- Our factory is located in Jiangsu province,more than 200 workers in our factory .

1.3- We sale good quality machines around the world with good service and got high reputation from our customer. Welcome to visit

our factory!

2.Can you customize machine ?

As a professional machinery manufacturer for more than 30 years,we have skilled OEM technique.

3. What about after sale service?

Engineer will go to buyer’s factory to install, test machines, and train buyer’s staff how to operate, maintain machines.

When machine has problem, We will solve basic questions by telephone, email, whatsapp, wechat and video call.

Customers showing us the picture or video of the problem. If the problem can be easily solved , we will send you solution by video

or pictures. If the problem out of your control, we will arrange engineer to your factory.

4.How about warranty and spare parts?

We provide 1 year guarantee and enough spare parts for the machine,and most of the parts can be found in local market also,also you

can buy from us if all the parts that over than 1 year guarantee.

5. How can you control the quality and delivery?

All our machines will be tested before packaging. Teaching video and packing pictures will be sent to you for checking,we promise

that our wooden packaging is strong enough and safety for long delivery .

6. What about the delivery time?

In stock machine:1-7days(depend on products).

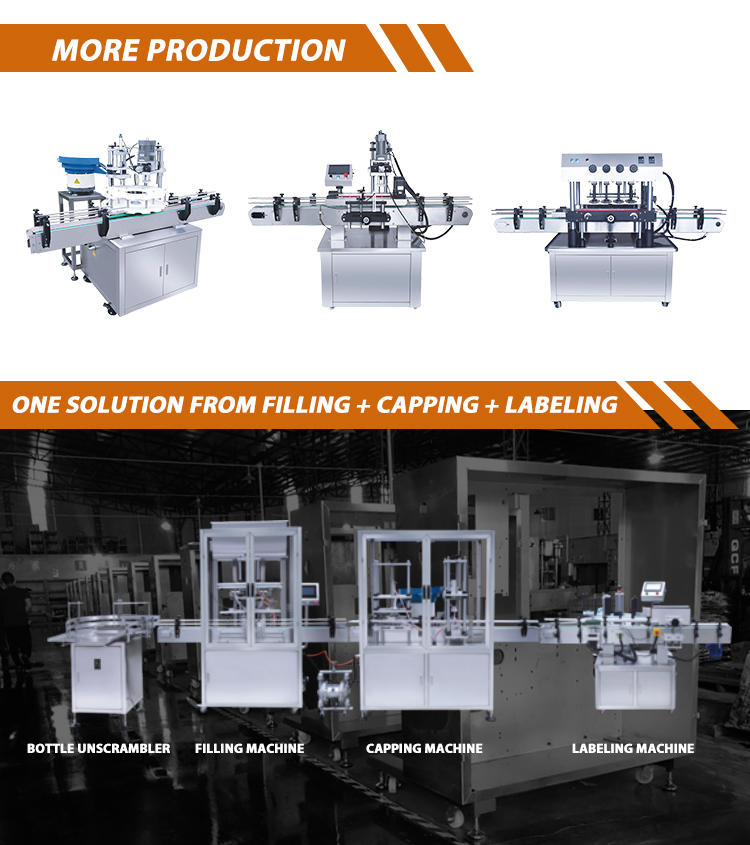

Product detail pictures:

Related Product Guide:

The client satisfaction is our primary concentrate on. We uphold a consistent level of professionalism, top quality, credibility and service for Factory Cheap Hot Bottle Cap Sealer - Rotary Capping Machine for 5ml filling sealing – BRENU , The product will supply to all over the world, such as: Washington, Seychelles, Belarus, We only supply quality products and we believe this is the only way to keep business continue. We can supply custom service too such as Logo, custom size, or custom products etc that can according to customer's requirement.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly