Filling

-

Coffee Capsule Filling Sealing Packing Machine (Coffee Powder Medicine Tea)

The name of coffee capsule is completely translated from the English name. The English meaning of capsule is capsule. Although it is a drink, it has a name like a medicine. However, the name does vividly reflect the characteristics of coffee capsules, which, like medicinal capsules, also contain powdered substances in the colloidal packaging. The advantage of coffee capsules is that because the capsule wall texture is relatively hard, it can maintain the prototype well at high temperature, so high-pressure water vapor can be injected into the capsule, so that the coffee can be completely precipitated under the action of pressure. Strong espresso, which can better ensure the aroma of the coffee. The main brands of coffee capsules are: Nespresso from Nestle, TASSIMO from JDE, K-cup, Oro from Italy (Owo, Lavazza, Monodor, ecaffe from Gaggia and Allcream from Korea), etc. -

Candy Gummy Chocolate Weighing Filling Packing Machine

Soft candy (gummy) is a kind of soft, elastic and tough functional candy. It is mainly composed of raw materials such as gelatin and syrup. After multiple processes, it constitutes a solid candy with different shapes, textures and flavors, which is exquisite and durable. Elastic and chewy,it like Candy gummy chocolate weighing filling packing machine

It is sealed in aluminum-plastic bags and packed into iron cans or transparent medicinal PET bottles. It is a mid-to-high-end nutritional product targeting children and young women.

-

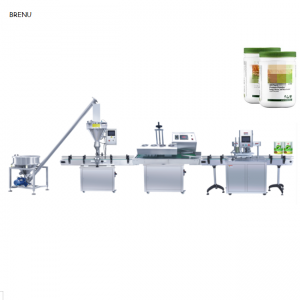

Powder Filling Capping Labeling Machine (Bottle Tin Container )

The powder filling machine is a powder filling machine, which is suitable for quantitative filling of powdery and granular materials such as pesticides, veterinary drugs, premixes, additives, milk powder, starch, condiments, enzyme preparations, and feed. -

Aluminum Metal Cap Filling Capping Labeling Machine( Liquor Vodka Whisky Red Wine Oil )

The filling machine is one of the main equipments produced by the winery. It is based on foreign advanced technology and is a machine for automatic production according to the characteristics of liquor (viscosity, alcohol content, etc.). It can save a lot of manpower and material resources. Realize the automatic filling of various wines. Liquor filling machine adopts stainless steel body, compact structure, perfect control system, convenient operation and high degree of automation; parts in contact with materials are made of high-quality stainless steel, no process dead ends, easy to clean; high-speed filling valve, accurate liquid level No liquid loss to ensure filling process requirements; complete overload protection device can effectively protect equipment and operator safety; -

Carbonated Drink Online Filling Machine ( Beverage Juice Soda Beer Milk Coconut Water Wine Tea)

The beverage filling machine is a plastic bottle beverage filling machine, an integrated automatic filling and capping machine, and a multi-functional beverage filling machine. It is used for filling carbonated beverages, soda water, salt soda and other carbonated beverages, as well as non-sparkling beverages such as fruit juice beverages and purified water. It is a new type of filling machine with multi-purpose and high practicability. -

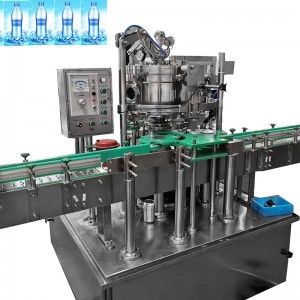

Pet Water Bottle Filling Machine (Water Tea Oil Without Carbonate)

Bottled water is drinking water packaged in a bottle for personal use and retail sale. The water it uses can come from anywhere, including spring water, well water, pure water, tap water, or even untreated or contaminated water.BRENU for water beverage filling machine more than 25 years , small or big capacity as request . -

semi auto Perfume filling machine

The perfume filling machine is suitable for the pharmaceutical, chemical, food, light industry and other industries to use vacuum negative pressure and self-suction filling equipment for glass, plastic, metal and other containers. The diameter of the machine used for the filled container should be small, and the diameter should be small. The expansion stress of the liquid surface should be greater than the hydrostatic pressure, which means that the liquid will not flow out by itself after the container is inverted. Such as oral liquid plastic bottles. Fengyou essence bottle, eye drops bottle, cosmetic perfume bottle, battery liquid filling and so on. -

Automatic Liquid Capsule Filling Machine

automatic hard-capsule liquid filling machine and sealing linkage line .the device can complete the filling of hard capsules (solution, suspension, microemulsion or hot solution) and sealing the capsule cap joint to make the capsule The contents are sealed in the process of packaging,transportation and use, which improves the stability and safety of the product. It can provide new modes of administration, improve the drug delivery problems of many drugs, and fill the domestic and foreign pharmaceutical and health care. -

Tube Filling And Sealing Machine

The automatic tube filling and sealing machine can realize various folding packaging of metal tubes. The same machine can easily realize the packaging of plastic tubes and metal tubes by changing molds and accessories. It is an ideal equipment for filling and sealing aluminum tubes, plastic tubes, and composite tubes in cosmetics, pharmaceuticals, food, adhesives and other industries, and meets the requirements of GMP specifications. -

Full Auto Capsule Filling Machine For Powder

the capsule filling machine is an intermittent motion and hole plate type filling fully automatic capsule filling equipment. It adopts optimization design combined the characteristics of Chinese medicine and requirements of GMP, it has the characteristics of compact mechanism, small volume, lower noise, precision filling dosage, multi-function, running stably etc. It can finish the following motion at same time: capsule feeding, capsule separating, powder filling, capsule rejecting, capsule locking, finished capsule discharge and module cleaning etc. This machine is designed for meet the volume-produce on the basis of model NJP-1200 automatic capsule filling machine, it increase the lifting mechanism that easy to clean, it saves the cost and manpower for the enterprise that need volume-produce. -

little capacity Filling and capping machine for eye drip

This Automatic Liquid Filling Capping Machine is using German advanced technology, engineering and technical personnel by the company independently developed specifically for liquid filling and capping. Filling part of the machine can be used 316L stainless steel injection pump filling, PLC control, high filling accuracy, easy to adjust the scope of the filling, capping method using constant torque capping, automatic slip, capping process does not damage material, to ensure the packing effect. The machine design is reasonable, reliable, easy to operate and maintain, in full compliance with GMP requirements. -

manual Tube Sealing Machine

tube sealing machine can realize various folding packaging of metal tubes. The same machine can easily realize the packaging of plastic tubes and metal tubes by changing molds and accessories. It is an ideal equipment for sealing aluminum tubes, plastic tubes, and composite tubes in cosmetics, pharmaceuticals, food, adhesives and other industries, and meets the requirements of GMP specifications.