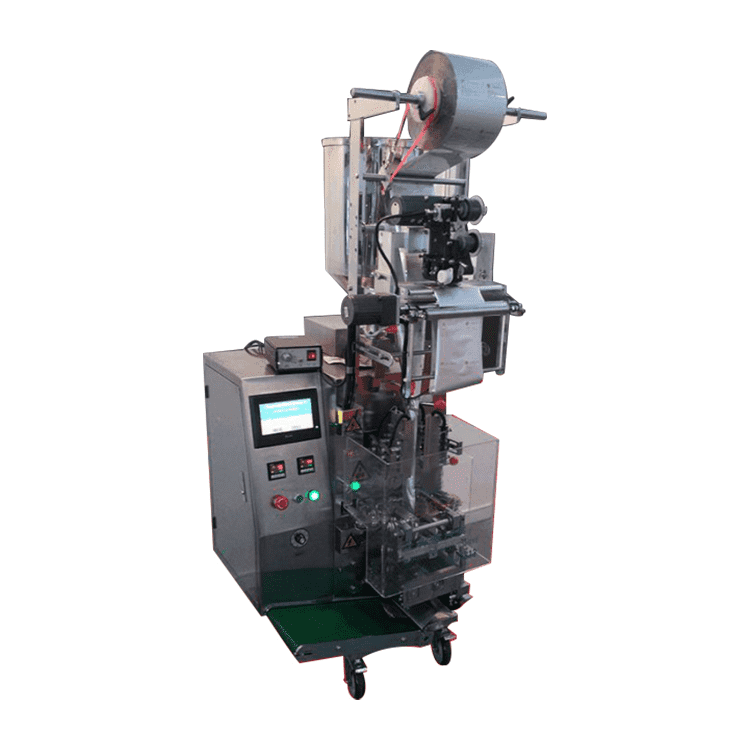

Factory Outlets Continuous Band Sealer Machine - Cartoning Machine with glue sealing date code – BRENU

Factory Outlets Continuous Band Sealer Machine - Cartoning Machine with glue sealing date code – BRENU Detail:

Cartoning machine is a kind of packaging machinery, including automatic cartoning machine, medicinal cartoning machine and so on. The automatic cartoning machine automatically loads the medicine bottles, medicinal plates, ointments, etc. and instructions into the folding carton, and completes the box closing action. Some of the more functional automatic cartoning machines also have sealing labels or heat shrink wrap. Package and other additional functions.

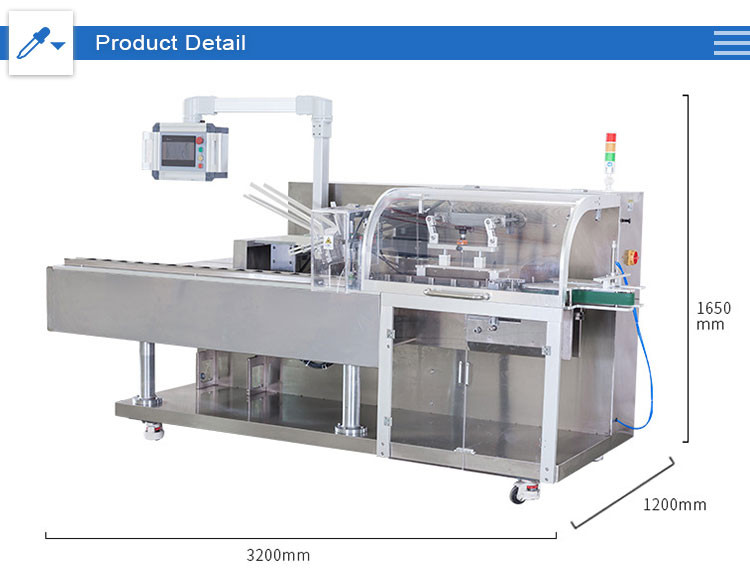

| Product Name | Box Cartoning Machine |

| Product Material | Paper weight:300- 350gsm/m3 |

| Size :Max (L*W*H)200X130X90mm,Mini(L*W*H)100X40X35mm | |

| Voltage | 220V 50HZ |

| Air consume | 20m3/h (pressure0.5-0.7mpa) |

| Dimension | 3600x1450x1600mm |

| Weight | 1100kg |

| Power | 1kw |

Character

1.auto feed , open the box , fill the box , sealing box and select box once time ;

2.Touch screen ,PLC control , high technology,operate easy ;

3. Photo electricity trace system check the ,remove the empty box , save the packing material ;

4.For difference packing size , adjustable easy ,no need change the mode ;

5.Auto protect system, once the goods not entry box fully ,or overloading ;

6.With the glass cover ,safety and beautiful ;

7.This machine can join with packing machine , 3Dpacking , filling machine , labeling machine ,code machine work together ,become the completely line ;

MATERIAL INTO THE BOX

The parallel pulling back of materials into the box is adopted to avoid equipment vibration , and the packing speed is faster and more stable

CONVENIENT ADJUSTMENT MODE

The vertical screw and hand wheel are adopted , the thickness of the paper box can be adjusted in a few seconds, the beam pressing device can be opened or pressed by one key ,and the operation is simple .

QUICK FASTENING BOX

The eccentric wheel disc is adopted to drive the box fastening device , so that the noise is low and the speed is high

FAQ

1.What guaranteeing does BRNEU offer?

One year on non-wear parts and labor. Special parts discuss both

2. Do installation and training included in the machinery cost?

Single machine:we done installation and test before ship, also supply competently video show and operate book ; the system machine :we supply installation and train service , the charge not in the machine , buyer arrange tickets , hotel and food ,salary usd100/day )

3. What types of packaging machines does BRENU offer?

We offer complete packing systems that including one or more of the following machines , also offer manual , semi-auto or full auto line machine . like crusher ,mixer , weight , packing machine and so on

4. How does BRENU ship machines?

We box smaller machines, crate or pallet larger machines. We ship FedEx, UPS, DHL or air logistic or sea , Customer pickups are protected well. We can arrange partial or full container shipping.

5. How about the delivery time ?

All small regular single machine ship in any time , after test and packing well .

Customized machine or project line from 15days after confirmed the project

Welcome contact us know more the tea packing machine , coffee packing machine , paste packing machine , liquid packing machine , solid packing machine ,wrapping machine , Cartoning machine , snack packing machine and so on

Product detail pictures:

Related Product Guide:

To continually enhance the management technique by virtue of your rule of "sincerely, great faith and high-quality are the base of company development", we widely absorb the essence of similar merchandise internationally, and continuously build new merchandise to meet the demands of customers for Factory Outlets Continuous Band Sealer Machine - Cartoning Machine with glue sealing date code – BRENU , The product will supply to all over the world, such as: Congo, Benin, Mauritius, You can always find the products you need in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We are looking forward to work with you for a win-win situation.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.