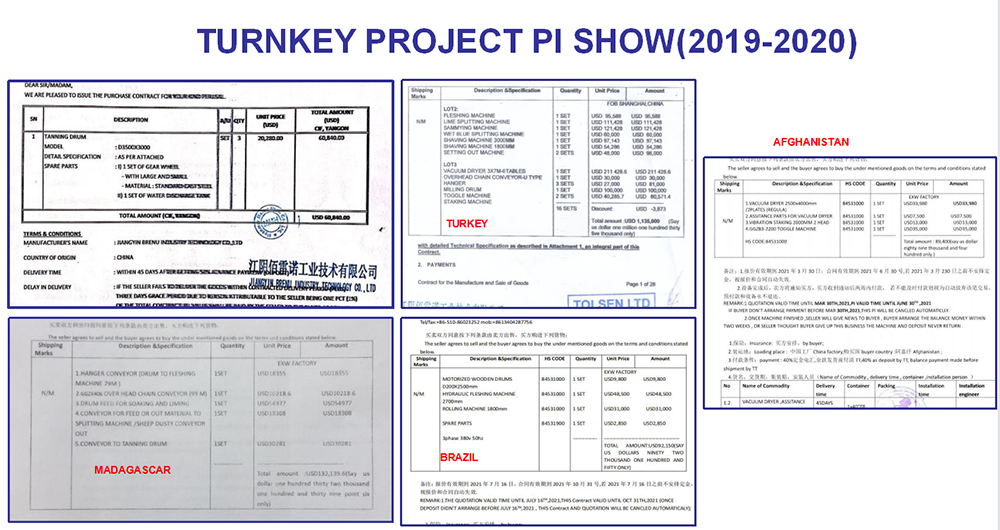

Fast delivery Liquid Paste Packing Machine - BRENU high quality and discount price Composite or monolayer LDPE film Ice pop lolly popsicle jelly online print filling sealing multi-function packing machines – BRENU

Fast delivery Liquid Paste Packing Machine - BRENU high quality and discount price Composite or monolayer LDPE film Ice pop lolly popsicle jelly online print filling sealing multi-function packing machines – BRENU Detail:

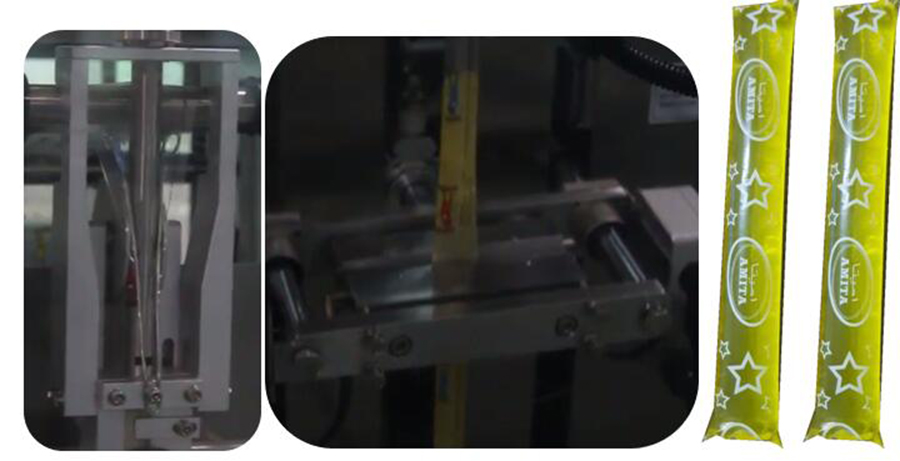

BRENU EXCLUSIVE TECHNICAL FOR ONLINE PRINT (a)

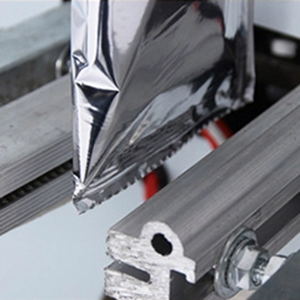

Because of the particularity of sealing, the traditional sealing packaging machine is mainly suitable for the packaging of composite film, the main materials are Paper/PE, PT/PE, PET/AL/PE, BOPP/PE, Tea filter paper and other compound materials can be heat sealed.

But for the packaging of popsicle, ice pop or jelly, the LDPE film which is cheap and easy to purchase is more preferred. The thickness of this material is 60-65 micro. The particularity of this material is a challenge for the structural setting of the equipment and the solution of material leakage.

BRENU, launched LDPE professional film packaging machine on the basis of combining material properties

Machine features

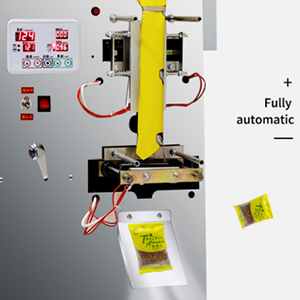

This machine can automatically complete all the work of measuring, bag making, filling, sealing, coding (option), cutting, counting, etc., and automatically completes the packaging of materials;

1. The servo can complete the measurement work more accurately;

2. Bag sealing: back sealing, mold shape and texture can be customized;

3. Ensure that the sealing effect is not affected, and the packaging speed can be adjusted;

4. Using advanced technology, user-friendly design, Japan “Panasonic” PLC+5.7″ touch screen control system, it is more convenient to monitor, control, and set production parameters in real time on the touch screen, with a high degree of automation;

5. Fault self-alarm, self-shutdown, self-diagnosis, safe and simple to use, fast maintenance;

6. Omron intelligent temperature control, the temperature of vertical sealing and horizontal sealing molds are controlled separately, controllable and adjustable, and the temperature deviation is ±1°C;

7. Functional status control: stop by ordering, accumulative production quantity, display production quantity, set total output stop, set filling weight;

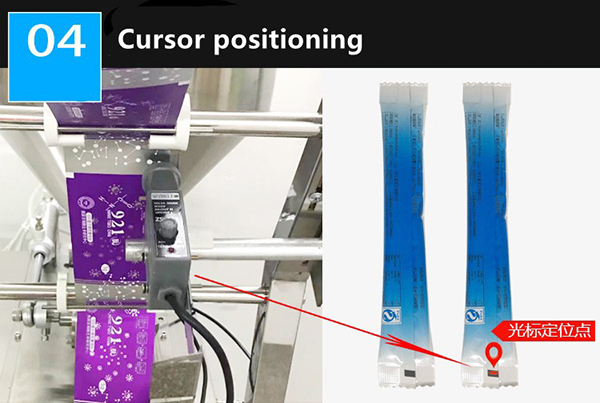

8. Using high-sensitivity electric eye, can automatically track and locate the printing cursor, and can obtain a complete trademark pattern when packaging packaging materials with color labels;

The whole machine is made of 304 stainless steel and aluminum alloy (complying with GMP standards), and the ground contact adopts universal wheels and adjustable lifting foot cups, which is convenient for changing the position and height of the equipment;

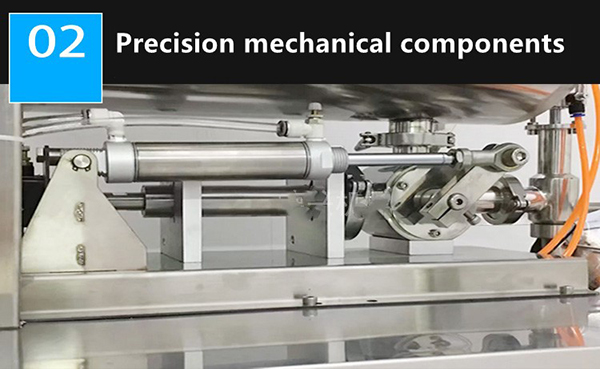

Machinery structure

|

No |

Part |

Detail |

Remark |

|

1 |

Sealing drive |

|

Servo motor |

|

2 |

PLC |

|

PLC+5.7 touch screen control system |

|

3 |

Temperature control |

|

intelligent temperature control |

MACHINERY CHARACTER:

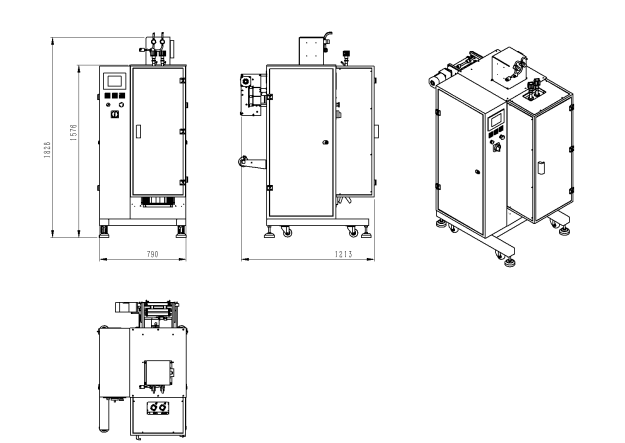

| NO | ITEMS | DESCRIPTION |

| 1 | Model | BRNL-600 |

| 2 | Material for filling | liquid |

| 3 | Measuring way | Time measuring |

| 4 | Sealing way | Back sealing |

| 5 | Date print | including |

| 6 | Sealing drive | servo |

| 7 | Precision | ±0.3-1% |

| 8 | Packing speed | 20-50bags/line |

| 9 | Film max width | 190mm |

| 10 | Film max length | 70-200mm |

| 11 | Bag width | 16-40mm |

| 12 | Sealing and cut layer | Two layer |

| 13 | Machinery material | Food grade stainless steel 304# |

ELECTRIC PARTS LIST

|

NO |

NAME |

MODEL AND SIZE |

BRAND |

Q’TY |

MARK |

|

1 |

PLC |

FP-XH-C40T |

Panasonic |

1 |

|

|

PLC expend |

AFPX-TR8 |

Panasonic |

1 |

||

|

2 |

Touch screen |

MT4414TE |

kinco |

1 |

|

|

3 |

Servo motor and driver |

LXM23DU10M3X |

Schneider |

1 |

|

|

4 |

Servo motor |

BCH1302N12A1C |

Schneider |

1 |

|

|

5 |

PID temp control |

AI-218-D1-G-L0 |

YUDIAN |

3 |

|

|

6 |

Middle relay |

RJ1S-CL-D24 |

China |

5 |

|

|

7 |

Middle relay base |

SJ1S-05B |

China |

5 |

|

|

8 |

switch |

YW1L-M2E01Q4G |

China |

1 |

|

|

10 |

Urgent stop switch |

YW1B-V4E01R |

China |

1 |

|

|

11 |

proximity switch |

PSE17-5DN |

Autonics |

3 |

|

|

12 |

safety door switch |

TZ-93B |

tend |

2 |

|

|

13 |

Color mark sensor |

KTM-WN11182P |

SICK |

1 |

|

|

14 |

slot switch |

EESX-671-WR |

OMRON |

1 |

|

|

15 |

2P circuit breaker |

NB1L-40 2P C10/2P+VE+30mA |

Chint |

1 |

|

|

16 |

2P circuit breaker |

DZ47-60 2P D15 |

Chint |

1 |

|

|

17 |

2P circuit breaker |

DZ47-60 2P D10 |

Chint |

1 |

|

|

18 |

Main power switch |

China |

1 |

||

|

19 |

switching power supply |

LRS-150-24 |

China |

1 |

|

|

20 |

solid state relay |

SAP-4825D |

3 |

||

|

21 |

Therm couple |

K(0-400degree) |

3 |

||

|

22 |

proximity switch |

GL-18H |

Panasonic |

2 |

|

|

23 |

proximity switch |

PSE17-5DN2 |

Autonics |

1 |

|

|

server Driver |

LXM23DU04M3X |

Schneider |

2 |

||

|

24 |

servo motor |

BCH0602O12A1C |

Schneider |

2 |

|

|

25 |

Material detection switch |

CR30-15DN |

Autonics |

1 |

|

|

26 |

slot switch |

EE-SX671A |

OMRON |

1 |

|

|

29 |

Detection electric eye |

PZ-G42N |

keyence |

1 |

|

|

30 |

proximity switch |

PR08-2DN |

AUTONICS |

2 |

BRENU EXCLUSIVE TECHNICAL FOR ONLINE PRINT (b)

The packaging film is generally printed and then packaged by color code detection. Due to the fast speed of the printing machine, the printing ink is a plastic ink, which is not environmentally friendly, the cost of plate making is high, and the MOQ is large. For small customers and R&D customers, the project is blocked. In order to help customers reduce the MOQ and cost, and realize the needs of more and customized pictures, a single-color or multi-color independent inkjet printer is hereby installed on the packaging machine. The machine feeds the material and sets the transmission signal of the final packaging size. After the printer receives the transmission signal, it will automatically print a single or multiple colors, so that the bag is formed, filled and printed at the same time. Help customers to achieve on-demand printing and on-demand printing of different patterns, instead of the trouble of mass printing MOQ, instead of expensive plate making, and the printing ink is environmentally friendly ink, which can be completely used in the food industry, instead of normal Printing with plastic ink.

Machine features:

1. This machine can finish : forming bag–measuring–material filling—sealing—counting—date code printing, all the work automatically;

2. Photoelectric and tracing system or computer system can be provided without your specific requirements.

3. The controller has the advantages such as setting the length of the bag, the speed and quantity with buttons;

4. This machine can be installed to code printer for 1-3 lines characters such as production and expiry date according to your special request.

Applicable packing film:

Paper/PE, PT/PE, PET/AL/PE, BOPP/PE, Tea filter paper and other compound materials can be heat sealed.

The machine is suit for automatic filling and packing liquid/paste/sauce/cream item, such as milk, juice honey, hair shampoo, tomato paste, salad dressing, jam ect. The machine adopt the pneumatic pump dosing unit which have the machine advantage of suit for viscous liquid item with high efficient and reliable performance. The most important is the machine equip with small horizontal ribbon blender mixing machine, this will make the machine much suit for seasoning paste/sauce, such as chilli paste, for the mixing machine will have the paste evenly packaged with less weight

Specification:

|

Product Name |

Paste and liquid packing machine |

|

Weighting Range |

3-100 ml (±1%) |

|

Maximum bag-making width Allowable bag-making length |

4-20 cm (Custom available) 4-16 cm (Custom available) |

|

Packing speed |

15-25bags/min |

|

Hopper volume |

30/50LL (Custom available) |

|

Package dimension |

63x39x100cm 30kg 90x55x117cm 77kg |

|

Power Supply |

110V/220V/230V/240V |

|

Power Consumption |

800W |

Machinery structure

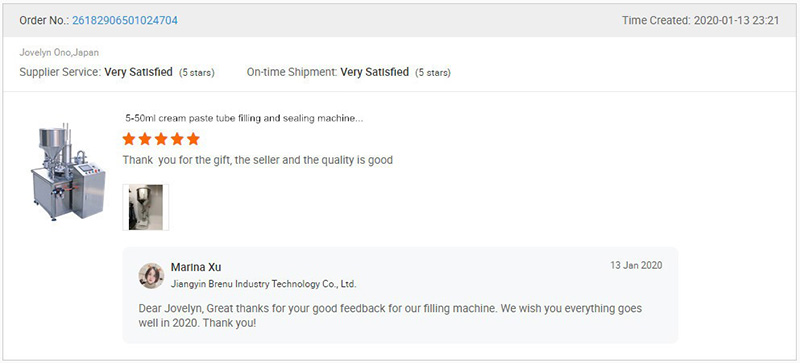

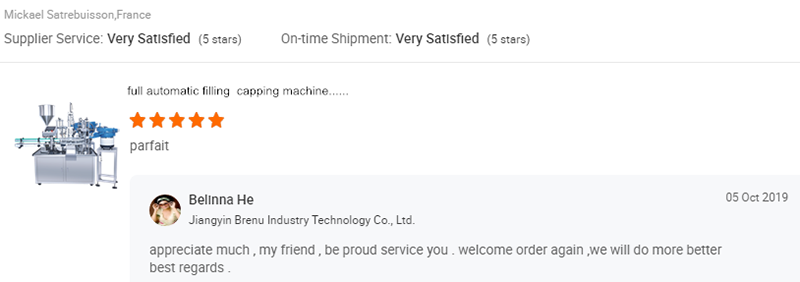

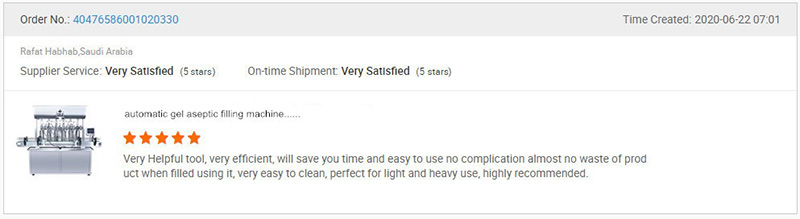

BUYER FEEDBACK

BRENU SERVICE

FACTORY SHOW

OUR PROMISE

SALES SERVICE ON LINE

① 24hours*365days*60minutes online service.

② team contact information for service .

Technical engineer :MR.JI (851439108@qq.com)

Online service:Lily(sales2@brenupackmachine.com)

Material Purchase manager:Tina(master@brenupackmachine.com)

Sales chief executive :Jessica(sales6@brenupackmachine.com)

③ If there are quality or other problems with our products,our company’s team will discuss it together and solve it, if it is our responsibility, we will never refuse to make you satisfied.

MACHINERY PARTS GUARANTEE :

Our company guarantees that all parts of the machine are original and authentic. During the one-year warranty period, our company will provide customers with free replacement parts and consumables for non-human damaged parts and consumables. Replacement is available to customers at cost price. Our company promises to provide life-long service for customer equipment, and only charge basic material costs and corresponding labor costs outside the warranty period.

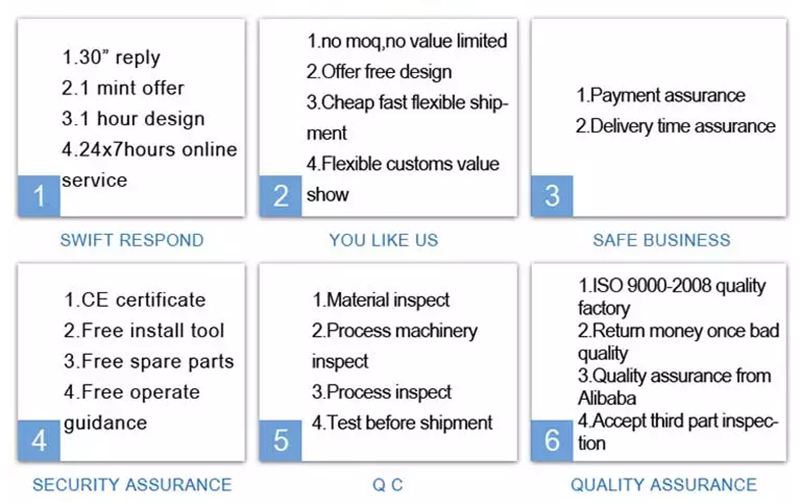

CHOOSE US YOU ARE BEST CHOICE :

SHOW OUR SERVICE TEAM PICTURE

SHOW OUR GUARANTEE CERTIFICATE FROM CEO

SHOW OUR GUARANTEE CERTIFICATE FROM CEO

Welcome contact :

what’s app:0086 13404287756

Quality guarantee :trade assurance by alibaba by manager and CEO

trade assurance protect : your money , delivery time and quality

JIANGYIN BRENU INDUSTRY TECHNOLOGY CO.,LTD

skype:belinna_2004mail:sales@brenupackmachine.com www.brenupackmachine.com

Product detail pictures:

Related Product Guide:

We normally think and practice corresponding towards the change of circumstance, and grow up. We aim at the achievement of a richer mind and body plus the living for Fast delivery Liquid Paste Packing Machine - BRENU high quality and discount price Composite or monolayer LDPE film Ice pop lolly popsicle jelly online print filling sealing multi-function packing machines – BRENU , The product will supply to all over the world, such as: Jeddah, Durban, Estonia, We'd like to invite customers from abroad to discuss business with us. We can present our clients with high quality products and excellent service. We're sure that we'll have good cooperative relationships and make a brilliant future for both parties.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.