New Delivery for Shrink Packaging Machine - multi-function packing machine for powder filling and sealing – BRENU

New Delivery for Shrink Packaging Machine - multi-function packing machine for powder filling and sealing – BRENU Detail:

Introduction:

multi-function packing machine , here show professional for the powder , from rough to fine or super powder pouch bag filling and sealing , the process starts with a cylindrical roll of film, the vertical bagging machine will transfer film from the roll and thru the forming collar (sometimes referred to as tube or plow). Once transferred thru the collar the film will then fold where upon the vertical seal bars will extend and seal the back of the pouch. Once the desired pouch length is transferred it is filled with product. Once filled the horizontal seal bars will then close, seal and cut the pouch providing a finished product that includes a bag with top/bottom horizontal seals and one vertical back seal.this machine as the bag filler including all industries like snack food , coffee , powders , frozen food , candy , chocolates , tea ,sea food and more

BHFP-300 MULTI-FUNCTION PACKING MACHINE

THE EXPERT OF THE POWDER POUCH FILLING AND SEALING MACHINE

This filler bagging machine Widely used for packing various powder in food, pharmaceutical industry, such as coffee powder, spice powder, tea powder, medical powder etc.

FIVE REASON SHOW WE ARE PROFESSIONAL

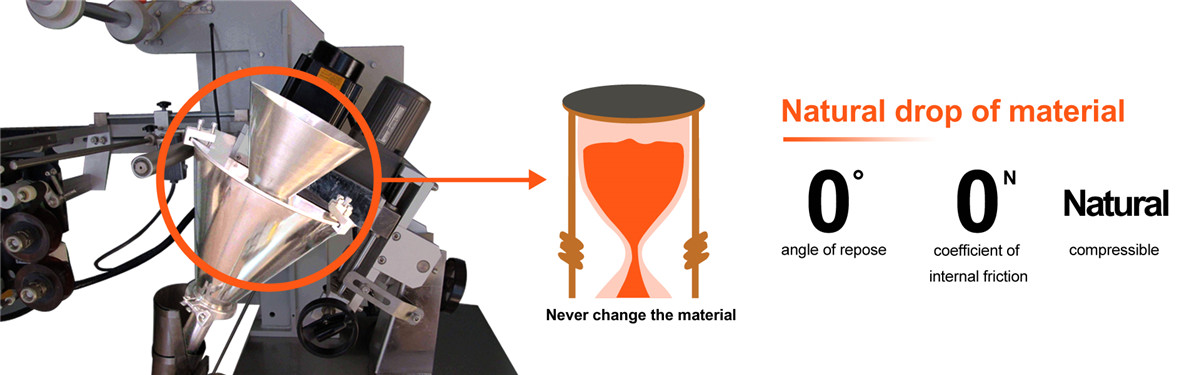

REASON 1: because the difference flow-ability of powder from grain to fine , the professional reasonably design most important ,try best reduce angle of repose , keep the natural compressible , down the coefficient of internal friction ,SUS 304 stainless steel for whole packing machine body from goods feeding ,frame and control box ,ensure the material touch the goods is food grade and enough smooth

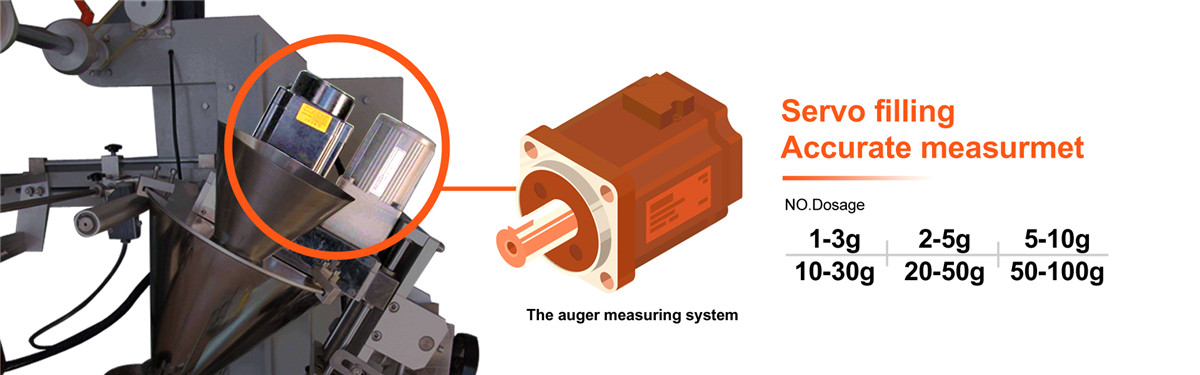

REASON 2: professional auger measuring system for this packing machine ,ensure the accurate measurement , the servo motor we bought from international brand

REASON 3:

PLC controlled display system, fault alarm system, circular wind electric control box design suitable for 24 hours working , the PLC from international brand

REASON 4:

During the roll film move , the film will change because of tension strength , the result make the finally bag length not exactly correct , our machine with the special device for adjust the whole film tension for keep the natural situation

REASON 5: International brand list for the packing machinery ‘s filling parts , sealing machine and whole machinery run key parts , top quality , long life that we always effort

CASE SHOW (BAG SIZE 15X14CM)

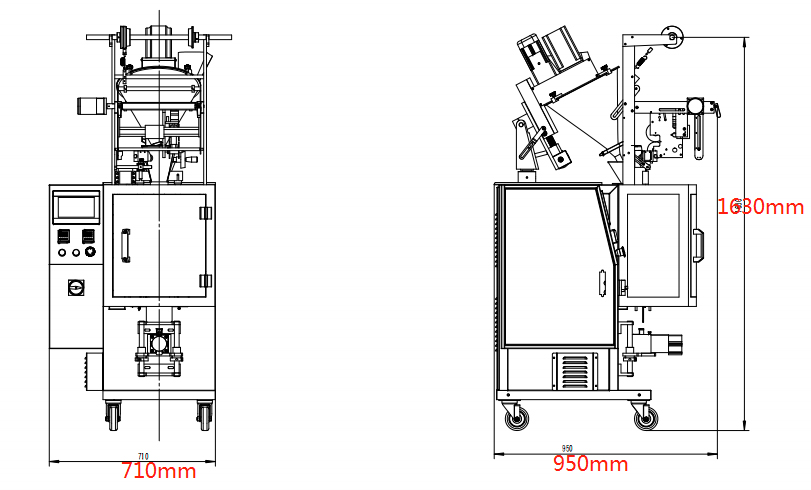

MACHINERY SIZE

TECHNICAL SPECIFICATION

|

Technical Specification |

Descriptions |

|

Capacity |

30-70 bags/min (determined by powder fluidity and the film) |

|

Sealing Type |

3-Side Sealing |

|

Sealing Method |

Heat Sealing |

|

Filling Range |

2-100 g |

|

Film Width |

50-280 mm |

|

Finished Bag Size |

W 25~140mm; L 30~180 mm |

|

Filling System |

Screw Conveyor |

|

Voltage |

220V; 50HZ; 1.9KW |

|

Driven Type |

Electric (and Pneumatic if seal round corner bag) |

|

Controller Screen |

WIENVIEW |

|

PLC System |

Mitsubishi |

|

Size and Weight |

L 950 x W 700 x H 1030 mm; 280 kg |

KNOW MORE BEFORE ORDER

WHICH TYPE PACKING MATERIAL SUITABLE ?

Packaging Materials: Polyester+polyethylene (PET/PE), Paper+polyethylene (PAPER/PE), Polyester/aluminum casting +polyethylene (PET/AL/PE), OPP+polyethylene (OPP/PE) etc which can be sealed by heating.

WHICH KIND OF MATERIAL YOU WILL PACKING , CAN SHOW US PICTURE?

Powder , sugar , salt , rice , grain , chemical , food ……

WHICH TYPE BAG FOR CHOOSE :

our packing machine , not only for bag filer , but also for sack sealing , you can choose the bag type depend your production ,three side sealing , back sealing or four side sealing . difference type the machinery structure difference , the cost difference

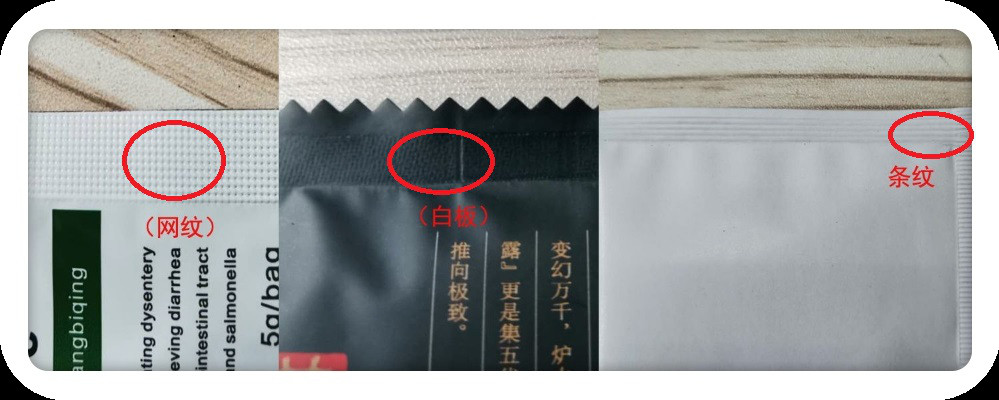

WHICH TYPE PATTERN YOU LIKE ?

HOW ABOUT THE BAG WIDTH AND LENGTH ?

Here the size we talked is the finished bag width and length ,after filling and sealing be the sack .

HOW ABOUT THE BAG WIDTH AND LENGTH ?

0-10G , 0-50G ,50-100G, 0-100G ,or other size .

HOW ABOUT THE GUARANTEE FROM BRENU OFFER ?

One year on non-wear parts and labor. Special parts discuss bu both

DO INSTALLTION AND TRAINING INCULDED IN THE MACHINERY COST ?

Single machine:we done installation and test before ship, also supply competently video show and operate book .

WHAT TYPES OF PACKING MACHINERY DOES BRENU OFFER?

We offer complete packing systems that including one or more of the following machines , also offer manual , semi-auto or full auto line machine . like crusher ,mixer , weight , packing machine and so on

HOW DOES BRENU SHIP MACHINES?

We box smaller machines, crate or pallet larger machines. We ship FedEx, UPS, DHL or air logistic or sea , Customer pickups are protected well. We can arrange partial or full container shipping.

HOW ABOUT THE DELIVER TIME ?

All small regular single machine ship in any time , after test and packing well .

Customized machine or project line from 15days after confirmed the project

The packing machine key parts special show :

Multilingual Touch Screen

Multi-language touch screen can switch various languages at the same time, and when there is a problem with the machine, it will automatically alarm, pause the operation and show where the machine is in the problem.

Pneumatic pump metering device

The exclusive patented technology device, using new custom pneumatic pump weighing, when the packaging weight is not accurate will automatically adjust to reach the preset weight, no manual operation to adjust, saving time and cost.

Servo Control System

Servo control system is used on machine weighing device, film pulling device, bag making and sealing. When there is a problem in one part, the machine will automatically stop running and alarm to remind the operator to check, therefore, one person can operate 15 machines at the same time to save cost.

FAQ

1.What guaranteeing does BRNEU offer?

One year on non-wear parts and labor. Special parts discuss both

2. Do installation and training included in the machinery cost?

Single machine:we done installation and test before ship, also supply competently video show and operate book ; the system machine :we supply installation and train service , the charge not in the machine , buyer arrange tickets , hotel and food ,salary usd100/day )

3. What types of packaging machines does BRENU offer?

We offer complete packing systems that including one or more of the following machines , also offer manual , semi-auto or full auto line machine . like crusher ,mixer , weight , packing machine and so on

4. How does BRENU ship machines?

We box smaller machines, crate or pallet larger machines. We ship FedEx, UPS, DHL or air logistic or sea , Customer pickups are protected well. We can arrange partial or full container shipping.

5. How about the delivery time ?

All small regular single machine ship in any time , after test and packing well .

Customized machine or project line from 15days after confirmed the project

Welcome contact us know more the tea packing machine , coffee packing machine , paste packing machine , liquid packing machine , solid packing machine ,wrapping machine , Cartoning machine , snack packing machine and so on

Product detail pictures:

Related Product Guide:

Reliable good quality and very good credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality 1st, purchaser supreme" for New Delivery for Shrink Packaging Machine - multi-function packing machine for powder filling and sealing – BRENU , The product will supply to all over the world, such as: Bahrain, Bogota, Dominica, Our products have won an excellent reputation at each of the related nations. Because the establishment of our firm. we've insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.