1

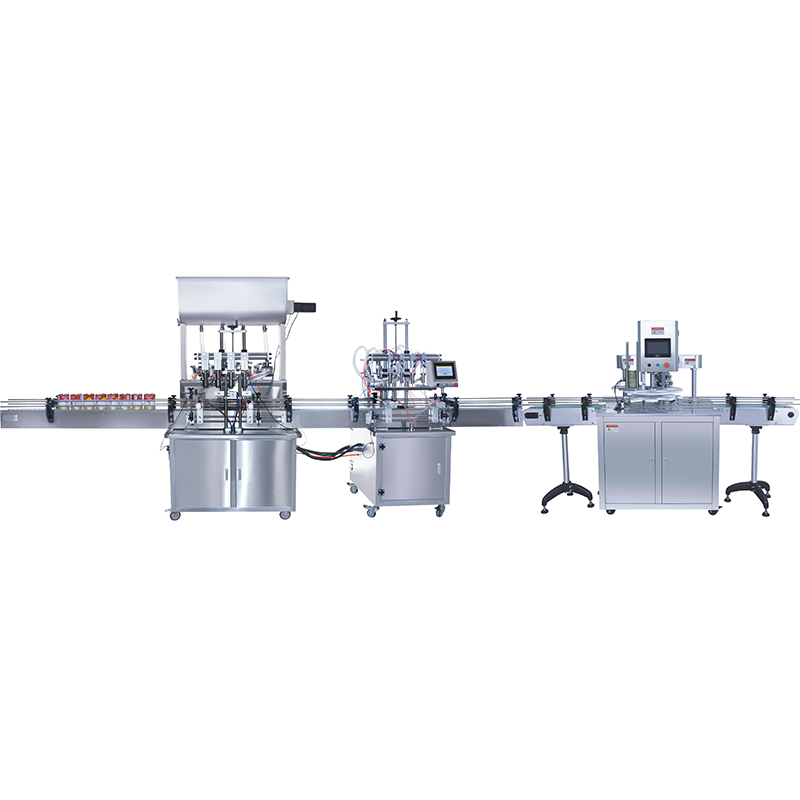

The filling and capping machine adopts piston servo drive principle, which is suitable for chili sauce, bean paste, ketchup, sesame paste, jam, butter hot pot base, red oil hot pot base, etc. with particles in condiments and high concentration. Filling of thicker sauces.

This machine is suitable for capping and sealing round and special-shaped glass bottles. It is the vacuum capping machine with the largest production capacity on the market. It is the first choice for large-scale production of food factories and canning factories.

2

The company’s glass bottle canned vacuum capping machine is equipped with a vacuum system, which can vacuum in the glass bottle to extend the long-term storage of the substance in the bottle and the richness of the taste. This machine can work continuously. In operation, it can perform automatic bottle feeding, automatic vacuum suction, automatic capping, and automatic bottle ejection. If equipped with related pneumatic control elements, it can also perform the function of no cap and no bottle.

3

3.1All parts of the machine contacting materials are made of sanitary stainless steel, which has good resistance to acid and alkali corrosion and meets GMP standards.

3.2 The machine adopts aluminum alloy body, stainless steel sealing plate, and protective doors on both sides, which is safe to use. The plastic shape is beautiful and generous.

3.3 It comes with a conveyor chain plate, the conveying speed is adjustable, and it can be operated by a single machine or with an assembly line.

3.4 It is equipped with a leak-proof and splash-proof structure, which effectively prevents dripping and splashing during material filling.

3.5 The hopper has a stirring mechanism, and the stirring speed is adjustable to ensure that the filled materials will not be blocked.

3.6 The hopper is equipped with a dust-proof device, which makes it difficult for dust and oil to enter the hopper, ensuring the sanitation of the material being filled.

Post time: Jan-25-2022