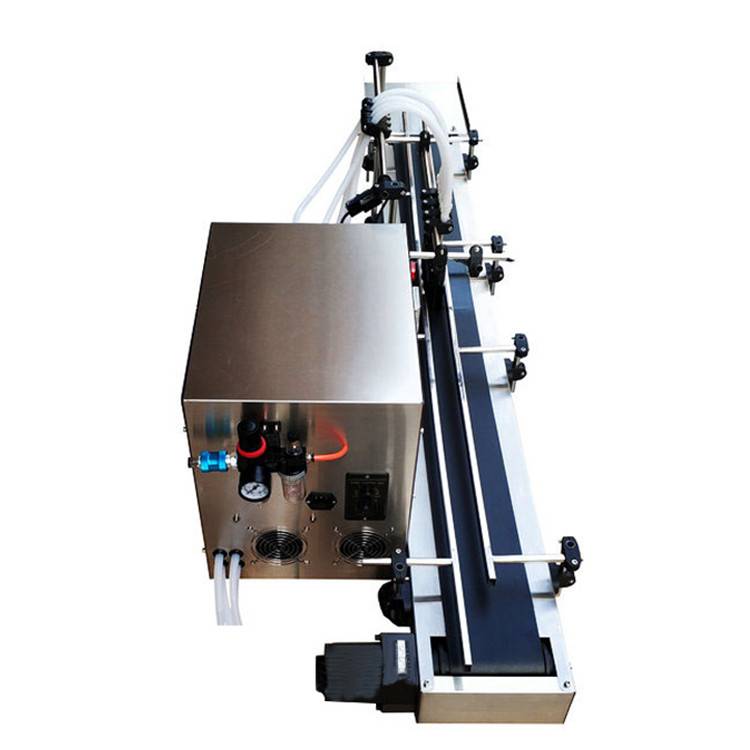

Popular Design for Powder Packaging Machine - four head Liquid digital control Filling Machine with conveyor – BRENU

Popular Design for Powder Packaging Machine - four head Liquid digital control Filling Machine with conveyor – BRENU Detail:

The desktop filling machine is used for quantitative dispensing of pharmaceutical liquids, refreshing drinks, cosmetics, etc. The whole machine is made of high-quality stainless steel, with a novel and beautiful appearance. And the quantitative is correct, the sub-assembly error is small, and the adjustment is simple. It is the most ideal small equipment for small-dose liquid quantitative packaging in hospitals, pharmaceuticals, pharmaceutical factories, beverage factories, daily chemical factories, scientific research experiments, etc.

The desktop filling machine is used for quantitative dispensing of pharmaceutical liquids, refreshing drinks, cosmetics, etc. The whole machine is made of high-quality stainless steel, with a novel and beautiful appearance. And the quantitative is correct, the sub-assembly error is small, and the adjustment is simple. It is the most ideal small equipment for small-dose liquid quantitative packaging in hospitals, pharmaceuticals, pharmaceutical factories, beverage factories, daily chemical factories, scientific research experiments, etc.

|

power supply |

220V (110V can be customized) |

|

Gas source |

0.4-0.7MPA |

|

power |

480W |

|

error |

±1% |

|

Operating mode |

Electrical combination |

|

Number of filling heads |

4 (customize) |

|

Filling range |

10-1000ml |

|

Conveyor length |

1.5m |

|

Feeding pump |

Food graded quality,2M/pc |

|

Pump head type |

Diaphragm pump (resistant to slight corrosion) |

|

Work capacity |

60-100 bottles/minute |

|

Machine size |

1500*500*400mm |

|

Maximum flow |

4000ml/head/minute (large flow can be customized) |

|

Body material |

304 stainless steel |

|

Packing |

Wooden box |

Feature

♦Especially suitable for liquid filling of 5-1000ml

♦Suitable for bottles of different specifications, adjustable

♦Microcomputer self-priming pump automatic quantitative, pneumatic induction positioning filling

♦Customize lifting and submersible filling, for foaming liquid

♦Accurate measurement, stable filling, simple operation, high-speed dispensing

♦Widely used in medicine, daily chemical, catering, food. Beverage and other industries

Product detail pictures:

Related Product Guide:

During the past few years, our business absorbed and digested state-of-the-art technologies the two at home and abroad. Meanwhile, our firm staffs a group of experts devoted to your development of Popular Design for Powder Packaging Machine - four head Liquid digital control Filling Machine with conveyor – BRENU , The product will supply to all over the world, such as: Austria, Pakistan, Slovak Republic, With the enterprising spirit of" high efficiency, convenience, practicality and innovation", and in line with such serving guidance of "good quality but better price, " and "global credit", we are striving to cooperate with the automobile parts companies all over the world to make a win-win partnership.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.