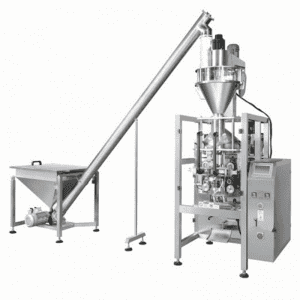

OEM Customized China Bg 1kg 2kg Vertical Filling Mix Flour Cocoa Baking Powder Almond Powder Packing Machine Price

For a result of ours specialty and repair consciousness, our business has won a very good name among the clients all around the globe for OEM Customized China Bg 1kg 2kg Vertical Filling Mix Flour Cocoa Baking Powder Almond Powder Packing Machine Price, Being a young increasing organization, we might not the best, but we have been trying our best for being your very good partner.

For a result of ours specialty and repair consciousness, our business has won a very good name among the clients all around the globe for China Avocado Powder Packing Machine, Ginger Powder Packaging Machine, Corporate goal: Customers’ satisfaction is our goal, and sincerely hope to establish long-terms stable cooperative relations with customers to jointly develop the market. Building brilliant tomorrow together!Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

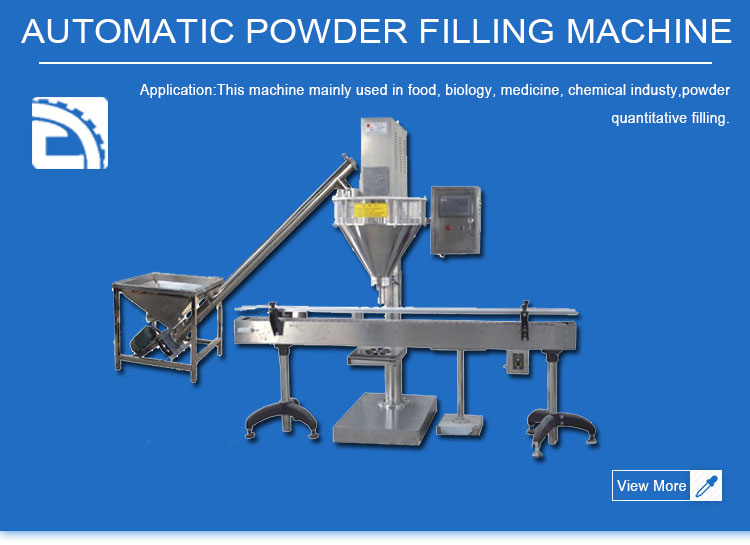

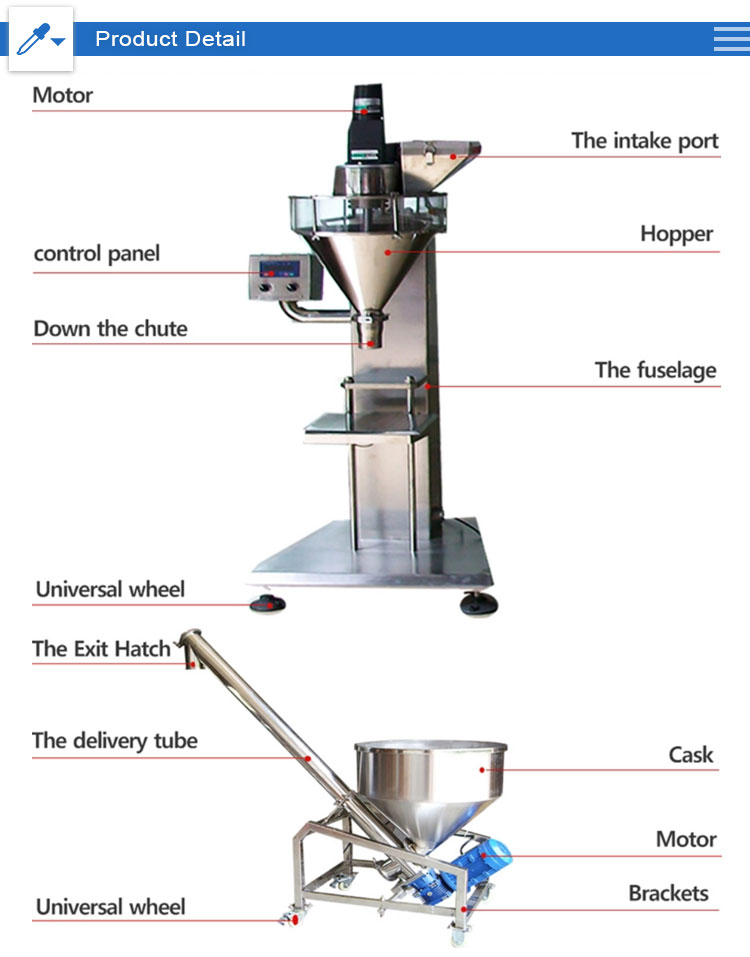

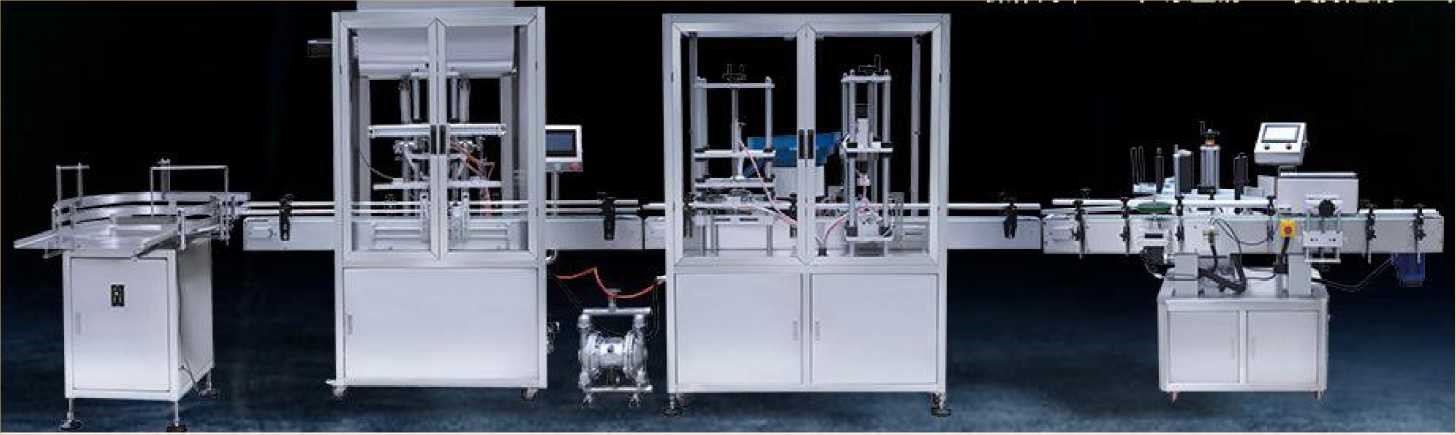

The powder filling machine is a powder filling machine, which is suitable for quantitative filling of powdery and granular materials such as pesticides, veterinary drugs, premixes, additives, milk powder, starch, condiments, enzyme preparations, and feeds.

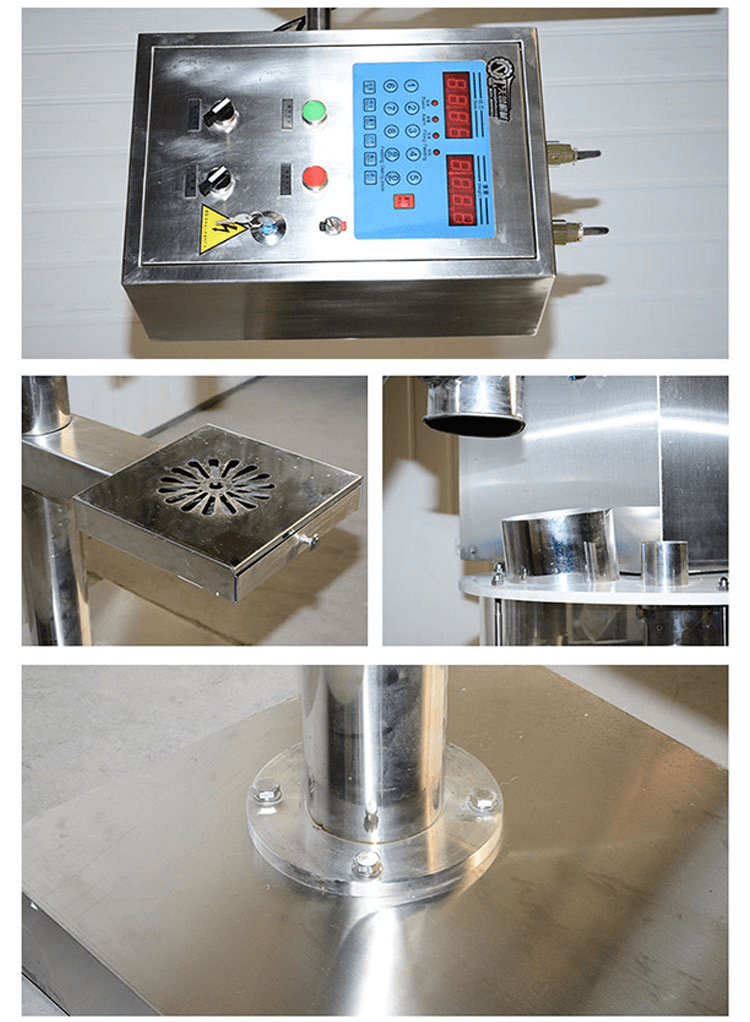

1. The powder filling machine is a combination of machine, electricity, light and instrument, controlled by a single-chip microcomputer, and has the functions of automatic quantitative, automatic filling, and automatic adjustment of measurement errors.

2. Fast speed: adopt spiral cutting and light control technology.

3. High precision: Step motor and electronic weighing technology are adopted.

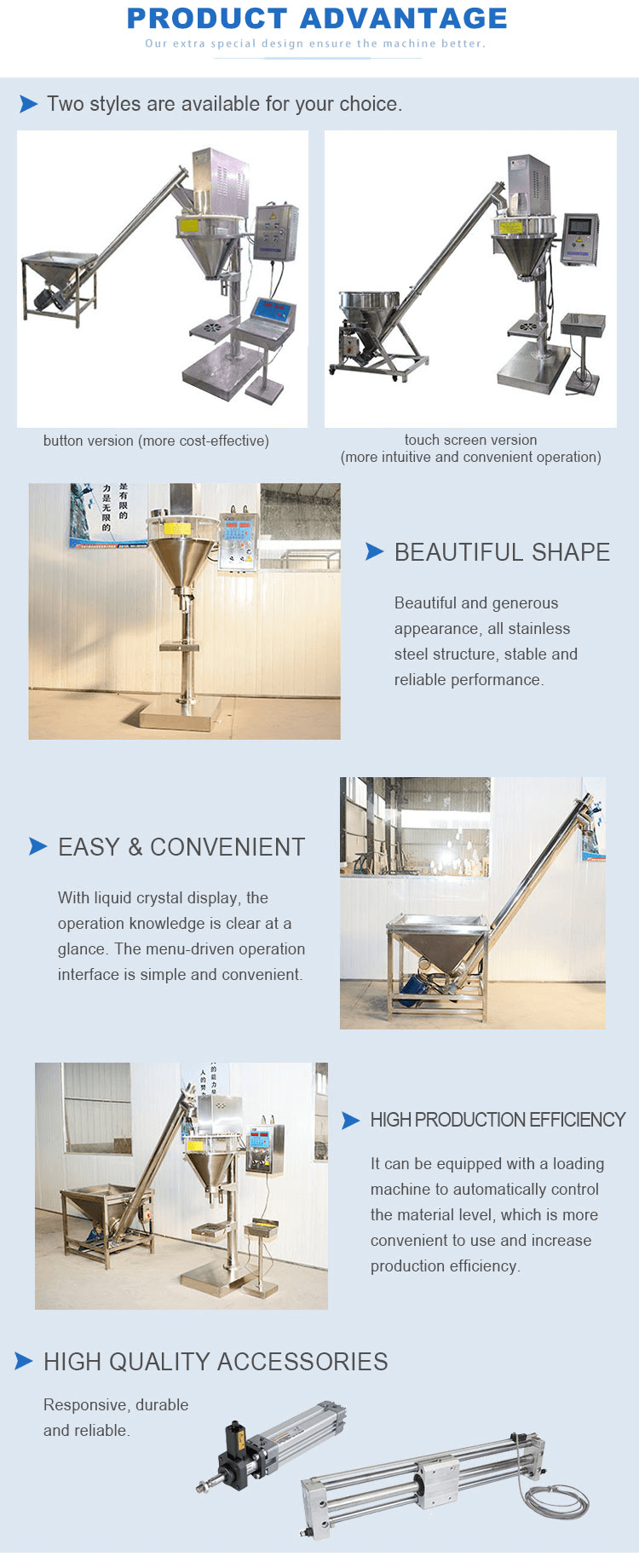

4. Wide filling range: the same quantitative filling machine can be adjusted continuously within 5-5000g through electronic scale keyboard and changing different specifications of the blanking screw.

5. Wide application range: both powdery and granular materials with certain fluidity can be used.

6. It is suitable for the quantitative packaging of powder in various packaging containers such as bags, cans, and bottles.

7. Errors caused by changes in material specific gravity and material level can be automatically tracked and corrected.

8. Photoelectric switch control, only need manual bagging, the bag mouth is clean and easy to seal.

9. The parts in contact with materials are made of stainless steel, which is easy to clean and prevent cross contamination.

Powder Filling Machine

| Packing materials | powder |

| Equipment material | material contact part is 304 stainless steel |

| Filling weight | 10-5000g (requires replacement of filling parts) |

| Weighing range | 1-1000g (weighing table) |

| Filling accuracy | >1% (different materials, degenerate) |

| Filling speed | 20 – 35 packs / minute |

| Power | 380/220v, 50-60HZ |

| Machine power | 3.2 KW |

| Machine weight | 150kg |

| Machine volume | 690×1060×2100mm |

| Bin capacity | 35L |

| Working principle | screw stepper motor drive |

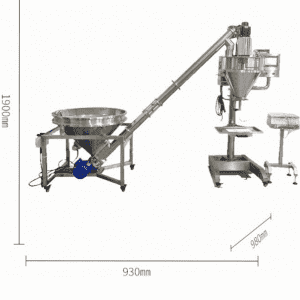

Feeding Machine

| Silo volume | 120 liters |

| Hopper size | 800x800x800 |

| Outlet from the ground | 1700mm (height can be designed as required) |

| Feeding speed | 3 cubic meters / hour |

| Total power | 1400W |

| Material | Stainless steel |

| Power supply | three-phase 380V |

1)Features:

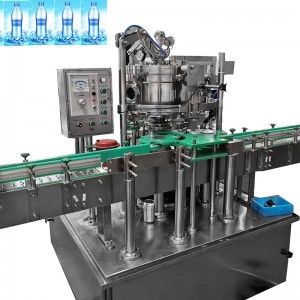

1.Suitable for all kinds of bottles, cans, bags of quantitative filling packaging container is not restricted.

2.Filling motor is a stepper motor or servo motor.

3.Stirring motor imported from Taiwan, free-noise motor.

4.Photoelectric sensor induction signal filling material, can also optional foot switch signal.

5.Feedback value can be adjustable, to meet a variety of precision required.

6.The filling motor speed can be adjustable, to meet the requirements of various materials.

7.All stainless steel, match with feeder enables automatic materials level control.

2) Functions:

1.Automatic error correction

2.Weight out-of-tolerance alarm

3.The product count

QC GUARANTEE

① all filling or capping machine from our factory ,QC personnel will carefully check the quality of the machine and do power-on test before the package leaves the warehouse.

②all filling or capping machine from our factory , There are special QC equipment to help QC personnel complete the inspection.

③all filling or capping machine from our factory ,QC stipulates that after each inspection, the quality inspection report must be filled in to ensure the quality of customers’ goods.

AFTER-SALES SERVICE

① all filling or capping machine from our factory ,24hours*365days*60minutes online service. engineers, online sales, managers are always online .

② all filling or capping machine from our factory ,We have a complete set of after-sales service process.

Technical engineer :MR.JI (851439108@qq.com)

Online service:Lily(sales2@brenupackmachine.com)

Material Purchase manager:Tina(master@brenupackmachine.com)

Sales chief executive :Jessica(sales6@brenupackmachine.com)

③all filling or capping machine from our factory , If there are quality or other problems with our products,our company’s team will discuss it together and solve it, if it is our responsibility, we will never refuse to make you satisfied.

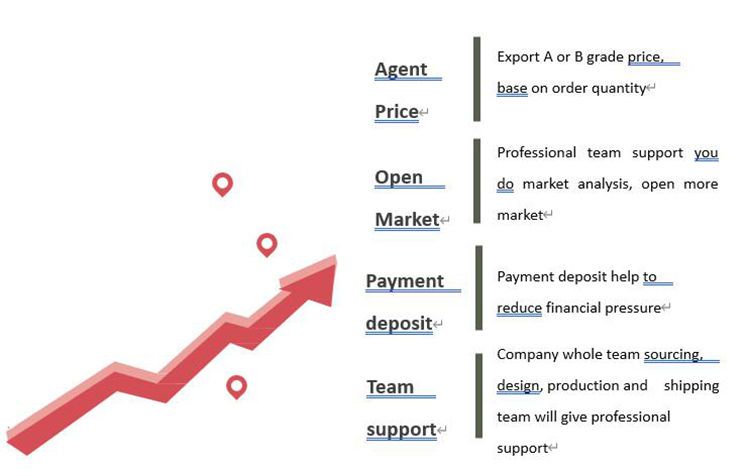

SPECIAL SERVICE FOR OUR AGENT

FAQ

1. Why choose us?

1.1- We have over 30 years experience on machinery making .

1.2- Our factory is located in Jiangsu province,more than 200 workers in our factory .

1.3- We sale good quality machines around the world with good service and got high reputation from our customer. Welcome to visit

our factory!

2.Can you customize machine ?

As a professional machinery manufacturer for more than 30 years,we have skilled OEM technique.

3. What about after sale service?

Engineer will go to buyer’s factory to install, test machines, and train buyer’s staff how to operate, maintain machines.

When machine has problem, We will solve basic questions by telephone, email, whatsapp, wechat and video call.

Customers showing us the picture or video of the problem. If the problem can be easily solved , we will send you solution by video

or pictures. If the problem out of your control, we will arrange engineer to your factory.

4.How about warranty and spare parts?

We provide 1 year guarantee and enough spare parts for the machine,and most of the parts can be found in local market also,also you

can buy from us if all the parts that over than 1 year guarantee.

5. How can you control the quality and delivery?

All our machines will be tested before packaging. Teaching video and packing pictures will be sent to you for checking,we promise

that our wooden packaging is strong enough and safety for long delivery .

6. What about the delivery time?

In stock machine:1-7days(depend on products).

MORE CUSTOMIZED FILLING MACHINE

PERFUME VACUUM LIQUID FILLING MACHINE

AUTO FILLING MACHINE

Contact us know more filling machine for more type machine including semi auto filling machine,full auto filling machine , customized design filling system : filling machine , capping machine ,sealing machine , labeling machine ,packing machine

For a result of ours specialty and repair consciousness, our business has won a very good name among the clients all around the globe for OEM Customized China Bg 1kg 2kg Vertical Filling Mix Flour Cocoa Baking Powder Almond Powder Packing Machine Price, Being a young increasing organization, we might not the best, but we have been trying our best for being your very good partner.

OEM Customized China Avocado Powder Packing Machine, Ginger Powder Packaging Machine, Corporate goal: Customers’ satisfaction is our goal, and sincerely hope to establish long-terms stable cooperative relations with customers to jointly develop the market. Building brilliant tomorrow together!Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.