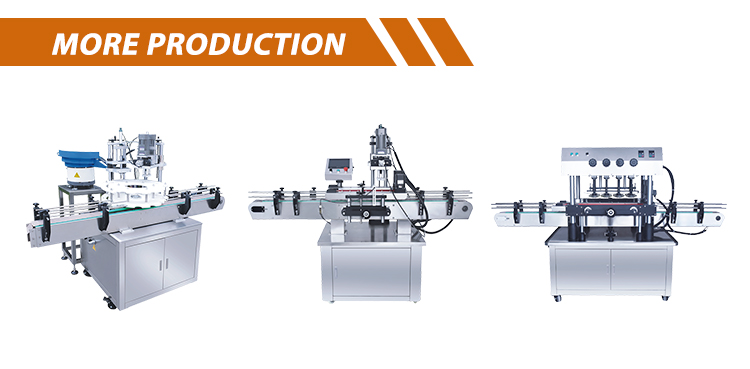

Tin can metal Capping Machine for beverage drink

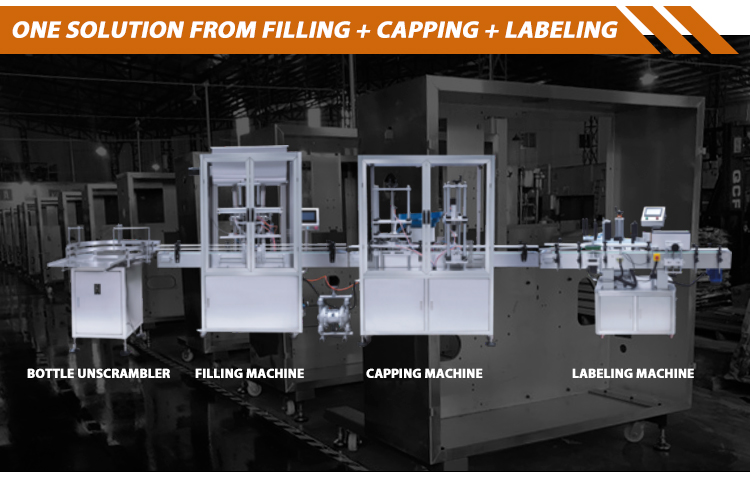

This automatic cans seaming machine is designed for sealing round bottles or round cans.It is suitable for plastic,PET ,ring-pull cans or paper cans.It is the ideal packaging machine for food,tea,pharmaceuticals industries.

THIS AUTOMATIC CANS SEAMING MACHINE IS DESIGNED FOR SEALING ROUND BOTTLES OR ROUND CANS , IT IS SUITABLE FOR PLASTIC , PET , RING-PULL CANS OR PAPER CANS , IT IS IDEAL PACKING MACHINE FOR FOOD , TEA ,PHARAMACEUTICALS INDUSTRIES .

| items | Technical | Detail |

| 0 | Model | BYS-31819 |

| 1 | Suitable bottle size | Bottle diameter 70-130mm |

| 2 | Bottle height | 60-190mm(other size customized ) |

| 3 | capacity | 30-60pcs/min (depending on bottle and caps) |

| 4 | Working voltage | AC220V/110V 50-60HZ 1.9KW |

| 5 | Dimension | 3000x1000x1500mm |

| 6 | Weight | 350kg |

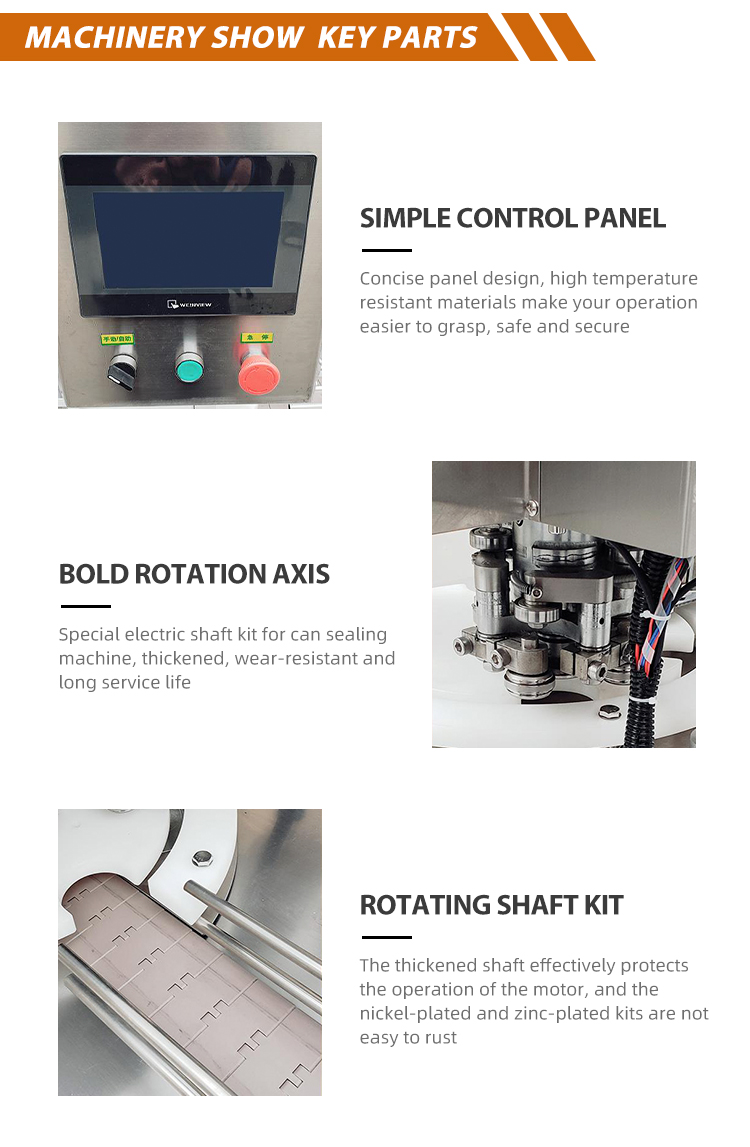

Mechanical parts: drive system and sealing parts

Pneumatic parts: the whole system

Sealing parts: electric is the energy with air cylinder working together

The capping machine, also known as the capping machine or the capping machine, here is rotary auto capping machine, which is divided into two parts: a handle and a capping head. There is a coil spring in the capping head to fix the four blades, and the rest of the capping machine except the two barrel springs is all cast from 304 stainless steel.

STRUCTURE AND PERFORMANCE SPECIFICATION

1. seaming rollers are made of stainless steel with high hardness and never rusty with excellent sealing performance

2.Electric appliance parts all use brand high and elements with reliable and steady performance

3. Latest generation design of can seam is non rotation of can body in the process of sealing , which avoids shift and scatter of product put well in the can

4. The machine precision is high , whole stainless steel materials are adopted fro main part to design requirements of manufacturing workshop

QC GUARANTEE

① all filling or capping machine from our factory ,QC personnel will carefully check the quality of the machine and do power-on test before the package leaves the warehouse.

②all filling or capping machine from our factory , There are special QC equipment to help QC personnel complete the inspection.

③all filling or capping machine from our factory ,QC stipulates that after each inspection, the quality inspection report must be filled in to ensure the quality of customers' goods.

AFTER-SALES SERVICE

① all filling or capping machine from our factory ,24hours*365days*60minutes online service. engineers, online sales, managers are always online .

② all filling or capping machine from our factory ,We have a complete set of after-sales service process.

Technical engineer :MR.JI (851439108@qq.com)

Online service:Lily(sales2@brenupackmachine.com)

Material Purchase manager:Tina(master@brenupackmachine.com)

Sales chief executive :Jessica(sales6@brenupackmachine.com)

③all filling or capping machine from our factory , If there are quality or other problems with our products,our company's team will discuss it together and solve it, if it is our responsibility, we will never refuse to make you satisfied.

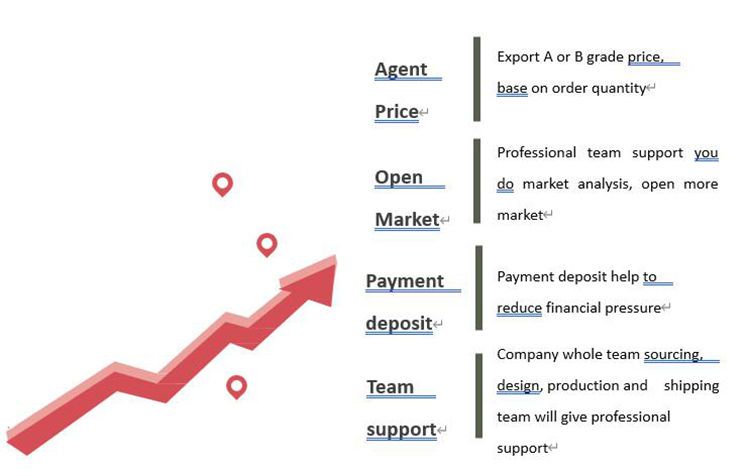

SPECIAL SERVICE FOR OUR AGENT

FAQ

1. Why choose us?

1.1- We have over 30 years experience on machinery making .

1.2- Our factory is located in Jiangsu province,more than 200 workers in our factory .

1.3- We sale good quality machines around the world with good service and got high reputation from our customer. Welcome to visit

our factory!

2.Can you customize machine ?

As a professional machinery manufacturer for more than 30 years,we have skilled OEM technique.

3. What about after sale service?

Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines.

When machine has problem, We will solve basic questions by telephone, email, whatsapp, wechat and video call.

Customers showing us the picture or video of the problem. If the problem can be easily solved , we will send you solution by video

or pictures. If the problem out of your control, we will arrange engineer to your factory.

4.How about warranty and spare parts?

We provide 1 year guarantee and enough spare parts for the machine,and most of the parts can be found in local market also,also you

can buy from us if all the parts that over than 1 year guarantee.

5. How can you control the quality and delivery?

All our machines will be tested before packaging. Teaching video and packing pictures will be sent to you for checking,we promise

that our wooden packaging is strong enough and safety for long delivery .

6. What about the delivery time?

In stock machine:1-7days(depend on products).