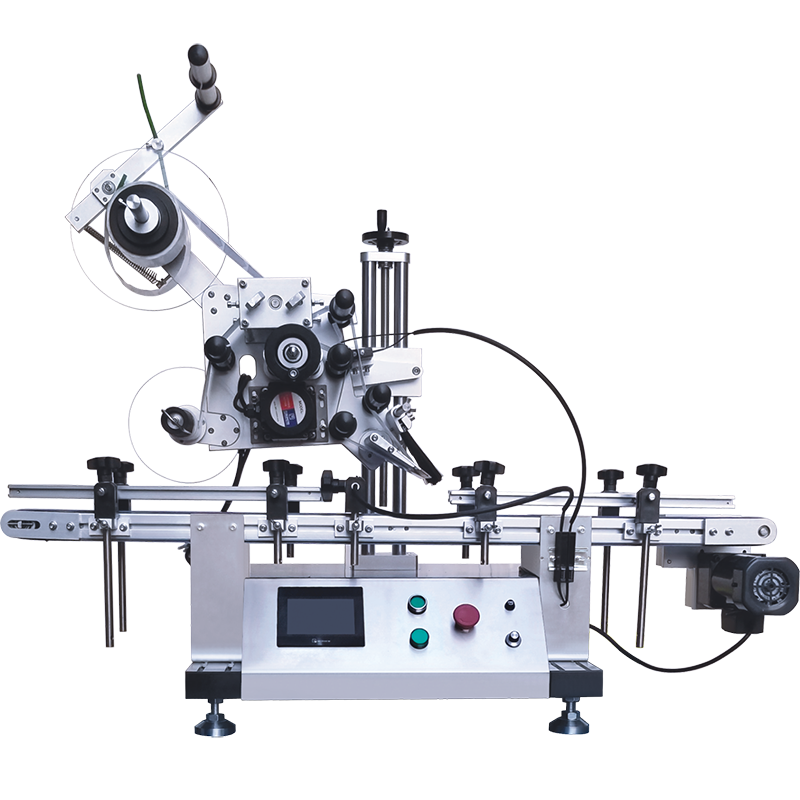

Semi Automatic flat Labeling Machine

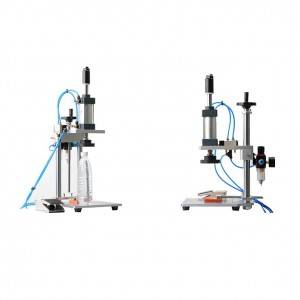

Semi-automatic flat labeling machine Basic use Apply suction labeling method to label, realize labeling on the flat surface of various workpieces, such as cosmetic flat bottles, packaging boxes, plastic cap labeling, etc.

The flat labeling machine is a device that sticks paper or metal foil labels on the specified packaging containers with adhesives. The flat labeling machine can complete automatic front and back double-sided labeling. Automatic labeling of both sides and the circumference of round bottles for various flat and square products in the industry.

The plane labeling machine realizes the labeling and filming on the upper plane and the upper curved surface of the work piece, such as boxes, books, plastic shells, etc. There are two methods of rolling and sucking, and the selection is mainly based on efficiency, accuracy and bubble requirements.

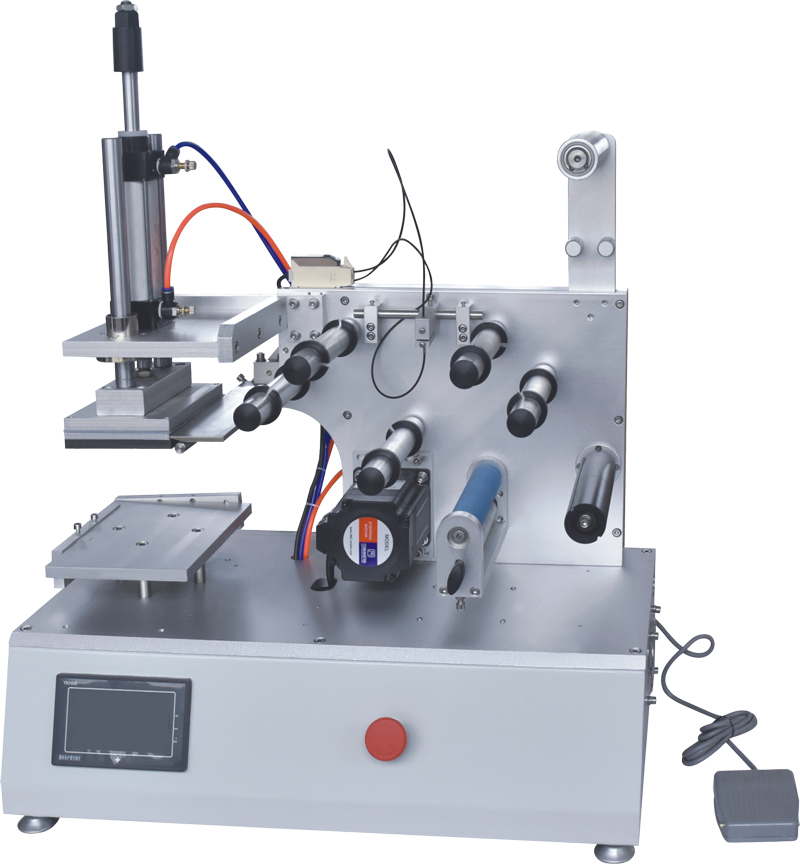

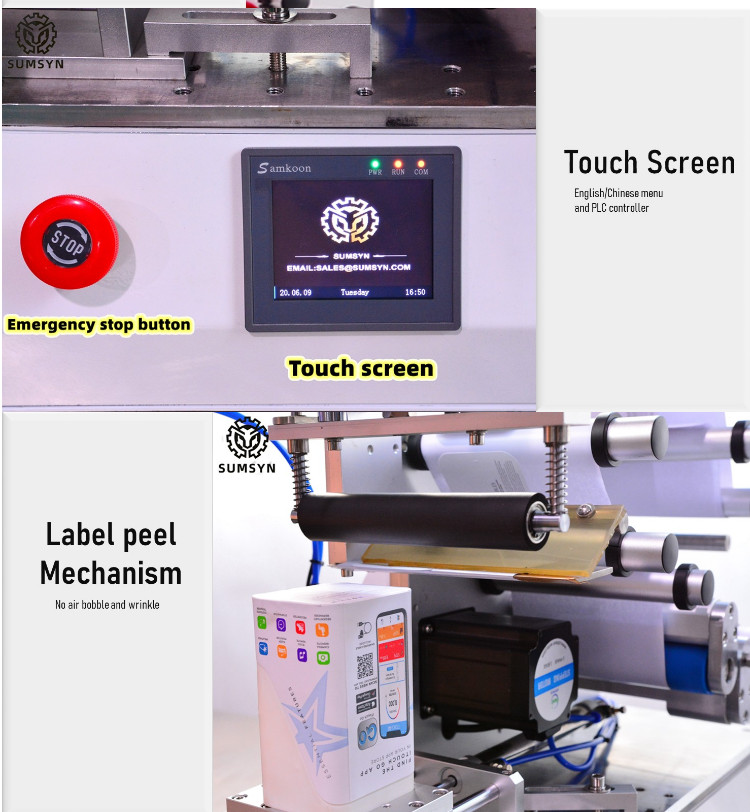

Humanized touch screen: simple and intuitive operation, complete functions, and rich online help functions for labeling machine

·Designed for flat, square and other irregular surfaces and curved bottle bodies to ensure labeling accuracy and effect: double-sided chain belt correction device to ensure the neutrality of flat and square bottles; special elastic top pressure device to ensure the bottle body stability for labeling machine

·Combined labeling machine, wide range of application: It can be converted between double-sided sticking and circular sticking with simple adjustment for labeling machine

Optional detection eye for transparent labels to improve detection accuracy for labeling machine

·Labeling parameter storage function (20 groups of labeling parameters can be preset, no need to reset when changing bottles) for labeling machine

Optional configuration such as coding machine can complete coding and labeling synchronously, and can warn the status of printing equipment for labeling machine

·It can be used both stand-alone and online for labeling machine

Machine Specification

| Detail | Specification |

| Applicable Product size | Hight: 0.2-100 mm Width:20-150 mm length: 20-200 mm |

| Applicable outer diameter of label roll: | φ280mm |

| Applicable inner diameter of label roll | φ76mm |

| Labeling precision | ± 0.5 mm |

| Labeling speed | 15 ~ 35 pcs/min |

| Weight | about 48 kg |

| Frequency | 50HZ |

| Voltage | 220V |

| Power | 145W |

| Overall dimensions of the machine (L × W × H): | 850 mm × 410mm × 720 mm |

| Air pressure | N/A |

1)The labeling machine available for labeling on many kind of surface

2)the labeling machine Accurate labeling and high stability

3)the labeling machine with Strong and durable, designed to prevent damage from environment

4)the labeling machine Easy to adjust , suitable for daily operate

5)the labeling machine Economic , the price is reasonable

6)the labeling machine with two controlling system :sensor/foot stepping

Optional functions and components:

(1)hot print coding / ink-jet printing function;

(2) Special label sensor;

(3) other functions (according to customers’ requirements).

QC GUARANTEE

① all filling or capping machine from our factory ,QC personnel will carefully check the quality of the machine and do power-on test before the package leaves the warehouse.

②all filling or capping machine from our factory , There are special QC equipment to help QC personnel complete the inspection.

③all filling or capping machine from our factory ,QC stipulates that after each inspection, the quality inspection report must be filled in to ensure the quality of customers' goods.

AFTER-SALES SERVICE

① all filling or capping machine from our factory ,24hours*365days*60minutes online service. engineers, online sales, managers are always online .

② all filling or capping machine from our factory ,We have a complete set of after-sales service process.

Technical engineer :MR.JI (851439108@qq.com)

Online service:Lily(sales2@brenupackmachine.com)

Material Purchase manager:Tina(master@brenupackmachine.com)

Sales chief executive :Jessica(sales6@brenupackmachine.com)

③all filling or capping machine from our factory , If there are quality or other problems with our products,our company's team will discuss it together and solve it, if it is our responsibility, we will never refuse to make you satisfied.

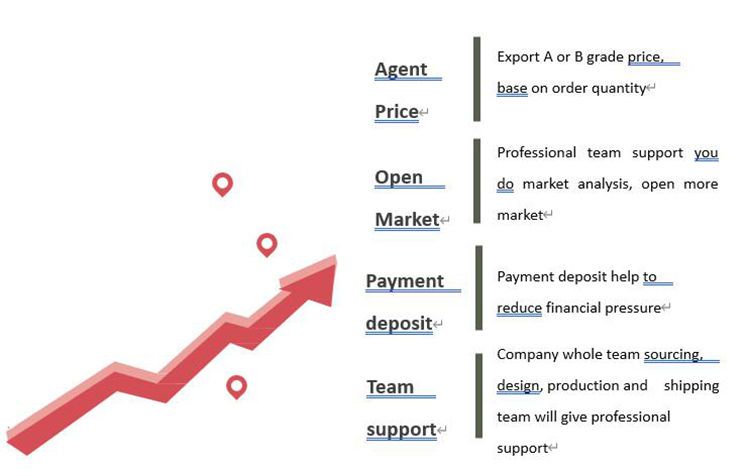

SPECIAL SERVICE FOR OUR AGENT

FAQ

1. Why choose us?

1.1- We have over 30 years experience on machinery making .

1.2- Our factory is located in Jiangsu province,more than 200 workers in our factory .

1.3- We sale good quality machines around the world with good service and got high reputation from our customer. Welcome to visit

our factory!

2.Can you customize machine ?

As a professional machinery manufacturer for more than 30 years,we have skilled OEM technique.

3. What about after sale service?

Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines.

When machine has problem, We will solve basic questions by telephone, email, whatsapp, wechat and video call.

Customers showing us the picture or video of the problem. If the problem can be easily solved , we will send you solution by video

or pictures. If the problem out of your control, we will arrange engineer to your factory.

4.How about warranty and spare parts?

We provide 1 year guarantee and enough spare parts for the machine,and most of the parts can be found in local market also,also you

can buy from us if all the parts that over than 1 year guarantee.

5. How can you control the quality and delivery?

All our machines will be tested before packaging. Teaching video and packing pictures will be sent to you for checking,we promise

that our wooden packaging is strong enough and safety for long delivery .

6. What about the delivery time?

In stock machine:1-7days(depend on products).

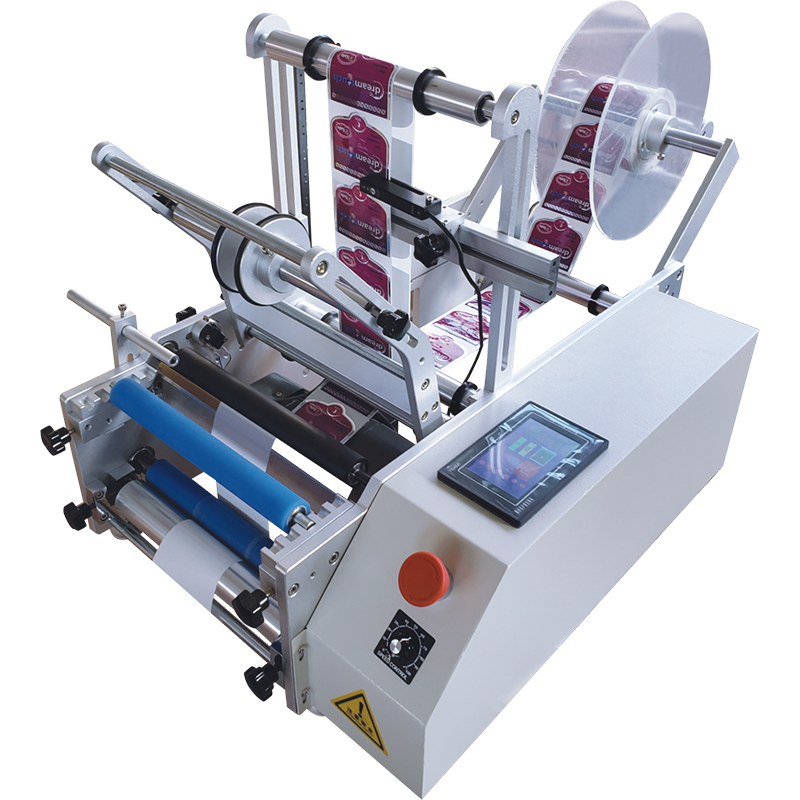

MORE LABELING MACHINE SHOW

Contact us know more filling machine for more type machine including semi auto filling machine,full auto filling machine , customized design filling system : filling machine , capping machine ,sealing machine , labeling machine ,packing machine